German researchers have succeeded in measuring the noise emitted by a turboprop aircraft synchronously on the ground and on the aircraft, a step forward that will help make future aircraft quieter.

The measurements were recorded during two flight tests for the FusionProp research project at Magdeburg-Cochstedt Airport in Saxony-Anhalt during last summer.

FusionProp started in April 2018 and involves the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) and GE Aviation in Munich.

The three-and-a-half-year long research program is developing numerical models to better predict turboprop noise. The two flight test campaigns were conducted to produce real-world data that is being used to develop and validate the models.

Propeller noise characteristics

Lorenz Drack, lead engineer from GE Aviation Munich said, “Parameters that affect the noise generated by a propeller are the rotational speed – the faster the blades rotate, the more noise is generated – flight speed, the amount of thrust required and details of the aerodynamic blade design.

“Under real flight conditions, the propeller noise generated is further complicated by aircraft attitude, turbulence, wind gusts, and effects resulting from the integration of the engine within the aircraft. Flight testing helps us understand the complexities of the noise generated by installed propellers, which in turn allows us to optimise our models”Propeller noise is caused by their special aerodynamic features and is the result of the relative motion between the propeller blades and the surrounding air. It is made up of both a tonal and a broadband component.

The tonal component is most likely to be perceived as a disturbance to the human ear and is caused by the displacement of air from the blade’s motion (thickness noise); the pressure field around the blades moving in the air (loading noise); and the unsteady periodic variation of loading on the blades due to, for example, the aerodynamic interaction with surrounding structures.

Broadband noise, on the other hand, occurs as a result of turbulence in the boundary layer of the blade, and the interaction of the blade with turbulence in the air.

Flight testing

Two flight tests were performed during summer last year as part of FusionProp. Both tests represented a full range of typical flight conditions including take-off, climb, cruise and approaches for landing.

In addition to instrumentation on and inside the two test aircraft, DLR’s DO 228 and a De Havilland Dash 8-400, more than 200 microphones were installed on the ground at Magdeburg-Cochstedt Airport.

Noise measurements on the ground were performed with the goal of improving noise prediction methods in areas surrounding airports and to enable noise source localisation using DLR’s large microphone array. More than 50 test points were investigated in numerous flights that were conducted with flyovers above the microphones, at several heights depending on the flight condition.

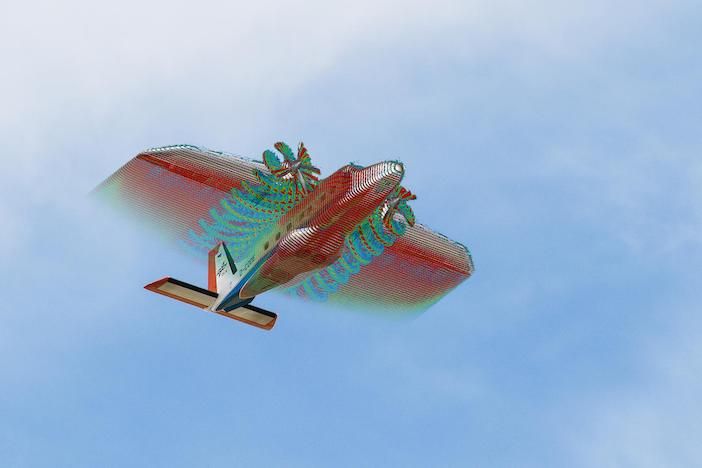

For the first time, synchronous flyover noise measurements were performed with a microphone array mounted on the fuselage of DLR’s DO 228 research aircraft, and two microphone arrays on the ground. The fuselage array and the ground arrays were developed at DLR with the goal of localizing the sources of noise.

“This is the first time we are able to correlate the noise arriving on the ground with the noise sources on the aircraft,” said Carsten Spehr from the DLR Institute of Aerodynamics and Flow Technology in Göttingen.

Future platforms

According to DLR, the research will enable engineers to more accurately predict the noise levels for a variety of installations, which will be important when developing future next-generation turboprop platforms.

Jimmy Barnard, product strategy and new technology leader at Dowty Propellers said, “With the emerging introduction of hybrid and all electric propulsion solutions in the industry, attention on the propeller as the main source of noise will increase.

“Developing new technology to ensure that the lowest possible noise is produced by a particular application has been a focus of Dowty Propellers’ research for a number of years.

“The FusionProp programme is seen as the culmination of a series of projects where technologies and tools undergo flight test evaluation to provide a platform for the validation of advanced noise prediction methods for propellers,” added Barnard.

“For certain flight conditions and with modern propeller configurations, installation effects can play an important role in the noise generated by propellers,” said Arne Stürmer, project manager at DLR. The evaluation and use of the measurement data can help make future aircraft quieter.

“In computer simulations, for example, we can check how to position of the propeller relative to the wing influences noise,” says Stürmer.

Researchers at DLR and GE Aviation are currently evaluating the large amount of data obtained during the tests.

This article was originally published on the DLR website and has been edited for style and length.