The Arnold Engineering Development Center (AEDC) at Arnold Air Force Base, Tennessee, USA, has announced a significant upgrade to its computational fluid dynamics (CFD) capabilities after a successful cooperation with CFD software provider Pointwise. A major component of the testing environment at AEDC is the ability to perform CFD analysis for a wide variety of flight conditions and physical environments.

James Masters, an AEDC engineer, explained that when using CFD, analysts must first properly define the region of interest so that the physics can be properly captured: “This is done by generating a computational mesh that fills the region and is usually accomplished through tools, such as the software package Pointwise.”

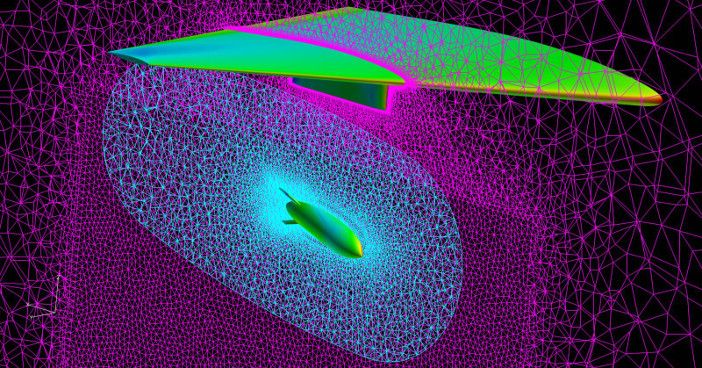

The Pointwise staff has been working with AEDC engineers to incorporate a capability known as overset meshing into their software. With overset meshing, multiple meshes can be used in a single region to better capture complex shapes like those of modern aircraft and test facilities. “It’s also valuable in CFD analysis because it allows bodies to move relative to one another,” Masters said.

As part of a recent contract extension with Air Force Material Command, the Pointwise team has completed tasks associated with an Air Force Small Business Innovation Research contract and is transitioning to a more extensive Commercial Readiness Program contract.

Nick Wyman, director of applied research for Pointwise stated, “This award validates our previous efforts in overset grid generation and assembly and will allow us to support the US Air Force’s need for a mission-ready simulation and modeling tool. The software developed during this project will provide analysis engineers with automated tools leading to significant reduction in overset mesh generation workload.”

The Pointwise software, and its predecessor Gridgen, have been used extensively at AEDC for many years. According to Masters, there are many aerospace-related applications that exist which require surfaces to move within a given region.

“This can include bodies moving relative to each other as [what] happens during a store separation event, or surfaces actually changing shape, which happens with ablation and aeroelasticity,” he said. “It also happens during design optimization, where many small perturbations to a given shape are required. Although there are many ways to handle surface motion, for certain applications, especially store separation, overset techniques are by far the most mature and efficient.”

Masters added there are currently many ways to do overset meshing but most are cumbersome and often involve outdated software packages. “The work being done by Pointwise using CRP funding will bring a modern approach to overset meshing where the interacting meshes can be easily visualized and problems can be quickly diagnosed and remedied. This has the potential to greatly improve the efficiency of setting up a CFD case involving multiple bodies and save considerable engineering man-hours.”

October 16, 2015