The UK-based Centre for Modelling and Simulation is to lead a three-year project to develop capability in several key areas of computational fluid dynamics simulation.

The not-for-profit Centre for Modelling & Simulation (CFMS) has its members companies from the aerospace, defense and automotive sectors and was formed in 2010 to provide a shared high-performance computing resource for engineering simulation and development.

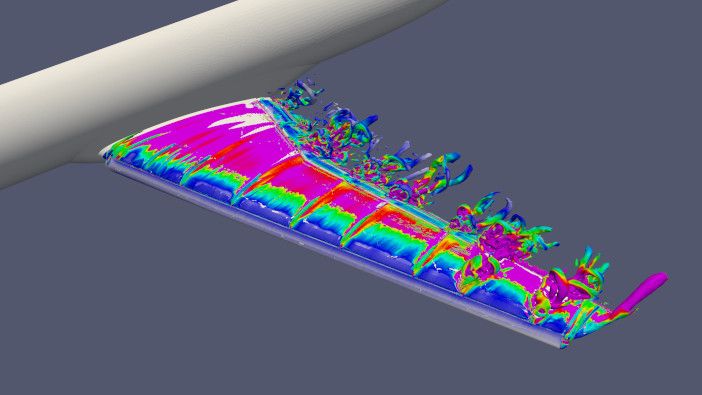

£1.55 million (US$1.87 million) Aero Flux project will see engineers from CFMS develop new simulation techniques for fluid-structure interaction, broadband acoustics, accelerated time-stepping, advanced high-order mesh generation and multi-disciplinary coupling. This will address the latest aerospace requirements with a greater level of accuracy, CFMS said.

The project will use CFMS’s computational infrastructure and advanced simulation knowledge to independently evaluate, test and benchmark the methods as they are developed. Using its access to cross-sector industrial and academic partnerships and regular programme of events, engineers at CFMS will disseminate its outcomes.

Sam Paice, chief operating officer at CFMS, said, “The development of new technologies from the Aero Flux project will offer greater flexibility and freedom in the high value design process, creating more accurate and efficient modelling tools. This will generate new opportunities, challenges and novel innovation, where physical testing of the end product will be reduced and the efficiency, speed and cost of the product development process will be improved.”

The project involves cloud-computing company Zenotech, research institute the Aircraft Research Association (ARA) and manufacturer Bombardier.

Zenotech will help to improve the CFD technique’s performance in aerospace applications, ARA will oversee the development of new high-order meshing tools for industrial use and Bombardier will present the industrial challenge and evaluation.