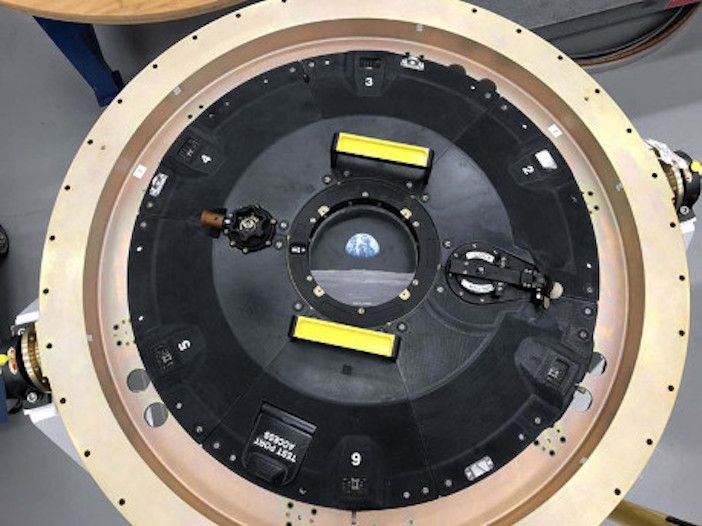

One of the 3D-printed parts to be used on the Orion spacecraft.

3D printer company Stratasys and 3D printing supplier Phoenix Analysis and Design Technologies (PADT) are partnering with Lockheed Martin to produce parts for NASA’s Orion deep-space spacecraft.

Orion will send astronauts to the Moon and beyond. Orion’s next test flight, dubbed Exploration Mission-1 (EM-1), will be the first integrated mission with the world’s most powerful rocket, the Space Launch System, where an un-crewed Orion will fly thousands of miles beyond the Moon during an approximately three-week mission.

The following flight, EM-2, will be the first manned mission to near the Moon since 1972. The mission will use more than 100 3D-printed production parts on board, developed in conjunction with Lockheed Martin, Stratasys and PADT.

The thermoplastic 3D-printed parts for NASA’s Orion vehicle are being produced at the Additive Manufacturing Lab at Lockheed Martin in conjunction with Phoenix Analysis and Design Technologies using Stratasys 3D printers and materials.

The materials to be used include an electro-static dissipative variant of Stratasys’ Antero 800NA, a thermoplastic that the firm says offers high performance mechanical, chemical and thermal properties.

Brian Kaplun, manager of additive manufacturing at Lockheed Martin Space, said, “Working with PADT, Stratasys and NASA has enabled us to achieve highly consistent builds that move beyond the realm of prototyping and into production.

“We’re not just creating parts, we’re reshaping our production strategy to make spacecraft more affordable and faster to produce.”

The 3D-printed parts to be used on the spacecraft include a critical component situated just outside of Orion’s docking hatch. The part consists of six individual 3D-printed components locked together to form a ring on the craft’s exterior.

April 18, 2018