Advanced acoustic testing equipment from US-company Acoustic Research Systems, used for testing spacecraft, is available in Europe after the company launched its testing services at an event in Toulouse last month.

US-company Acoustic Research Systems (ARS) officially launched its European operation at the event held at Le Grand Set in Toulouse, France at the end of April.

ARS’ purpose-built, turn key acoustic test system called Neutron can be used on a variety of test articles including spacecraft for launch simulation. The plug-and-play system can generate a completely incoherent, diffuse and homogeneous sound field up to levels and for test lengths the company says is not possible with previous line array systems.

The system can run semi or fully coherent should the application dictate and be used to drive reverberant chambers in replacement of, or in supplement to existing nitrogen driven transducers.

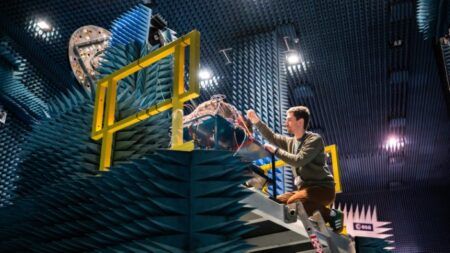

During the event at the film studio in Toulouse guests experienced a live Direct Field Acoustic Test experience. Representatives from companies including NASA, Airbus, ESA and Beyond Global experienced the Neutron System first-hand in its demo configuration.

The test configuration for the live experience comprised 12 Neutrons double stacked on a 12ft (3.66m) diameter, two Coreracks’s, one Arsdrive, 12 control microphones, four monitor microphones and a mock test article. The Neutron’s open test configuration allowed attendees to walk the periphery of the set-up and experience its design, scalability and fully incoherent, highly uniform field capabilities.

ARS European inventory is being housed in Potsdam, Germany, an expansion of the company’s US operations overseen by its director of European operations and general manager of ARS Tobias Wulf.

ARS co-founder and CEO, Jeremiah Leiter said, “It felt like a natural evolution to expand our inventory in order to better serve the highly-respected European market. Tobias is committed to providing the same level of service and unprecedented momentum that ARS has seen in the US, where precision, efficiency, and transparency have all been cornerstones, and will continue to be so in Europe.”

The announcement was made during April’s European Conference on Spacecraft Structures Materials and Environmental Testing, where co-founder and chief technology officer Eric Friedlander, presented a white paper co-authored with Wave6 and m+p international titled ‘Validation of Novel Direct Field Acoustic Test Workflow’ at the 17th Annual ECSSMET where all three companies exhibited.

“The paper looks at a new approach to utilise improved pre-test simulation, improve methods for post-test processing and complete the test loop of validating the model,” explains Friedlander.