Engineers from the German Aerospace Centre DLR have hot fired a 3D printed, full-scale, rocket thrust chamber assembly for the first time.

The BERTA (Biergoler Raumttransportaengine) engine will be used for the upper stages of rockets and used in-orbit transportation applications such as kick-stages and space-tugs, microlaunchers, and exploration spacecraft such as a lunar landers.

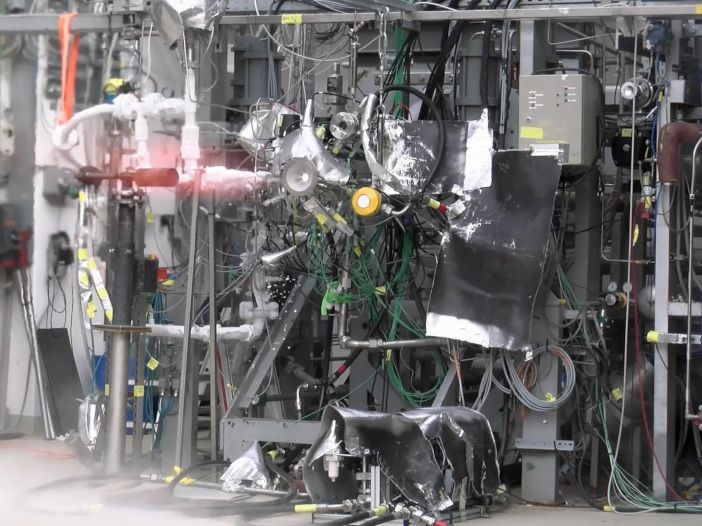

The recent hot firing of its rocket thrust chamber assembly at the Lampoldshausen testing facility in Germany marks a step forward for the project and for the use of 3D printing in engine manufacture, said the European Space Agency (ESA).

The combustion chamber demonstrator, with a reference thrust of 2.5kN, was hot-fired for 560 seconds.

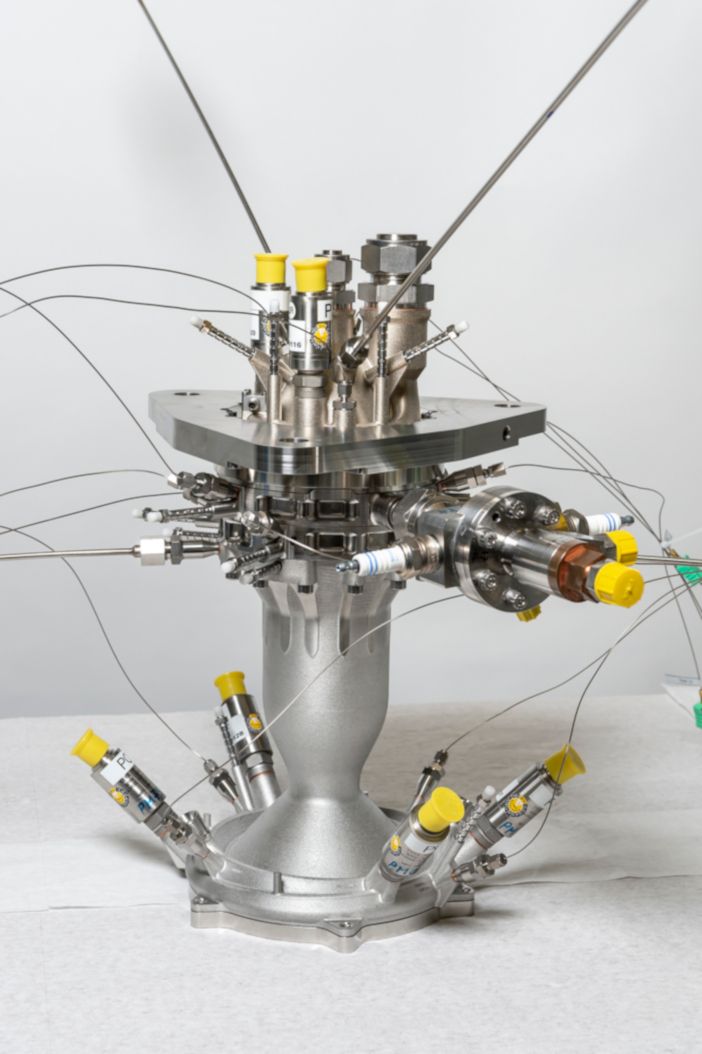

BERTA’s thrust chamber is designed for storable propellants, which can be stored as liquids at room temperature. Rocket engines that are powered this way are easy to ignite reliably and repeatedly on missions lasting many months.

Cooling channels

The knowledge gained from this test campaign will be applied to future engine designs to achieve a thrust range of about 2–10kN.

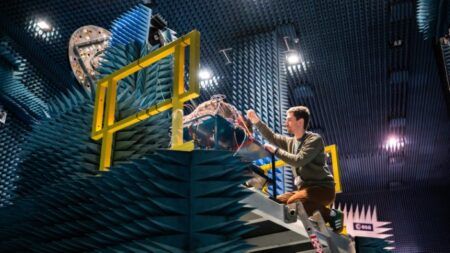

Developed by ArianeGroup within ESA’s Future Launchers Preparatory Programme, this combustion chamber helps to investigate flow and heat transfer phenomena on surfaces created by 3D printing – otherwise known as additive layer manufacturing.

A complex arrangement of cooling channels was printed into the structure of the combustion chamber, to cool the chamber walls.

Wenzel Schoroth, propulsion engineer at ESA said, “3D printing and qualifying parts for hot-firing and ultimately flight is a challenge, especially when dealing with fine, complicated structures, like the cooling channels of our demonstrator”

“This hot-fire test is a way of demonstrating the effectiveness of our processes, as well as learning more about the flow phenomena within additively manufactured rocket engines.”

Test arrangement

On the test bench, the cooling mechanism was diverted away from the propellant feed via an adaptor between the combustion chamber and the injector head – both of which had been additively manufactured.

This allowed engineers greater flexibility to investigate the cooling system separately from the combustion process and to study the thermodynamic and fluid dynamic properties of the additively manufactured structures and surfaces.

For the next step in the project engineers will focus on the application of environmentally friendly propellants for a larger engine delivering 5kN of thrust.

The ESA is developing additive manufacturing technology for larger engine demonstrators with cryogenic propellants such as Prometheus and ETID.