Lockheed Martin has successfully completed structural testing of the heat shield for NASA’s Mars 2020 rover.

The heat shield is half of a large two-part aeroshell designed and built by Lockheed Martin for the US$2 billion mission, which is expected to reach Mars during February 2021.

The 15ft (4.5m) diameter heat shield serves as a brake to slow the spacecraft from speeds of around 12,000mph (19,300km/h) as it descends through the Martian atmosphere. The structure of the shield has to be flawlessly smooth to ensure it can withstand the heat and friction of the Martian atmosphere – up to 2,200˚C (4,000˚F).

Last year, engineers at Lockheed managed to crack the heat shield during structural testing which exposed it to flight-like thermal conditions. The physical integrity of the aeroshell was finally validated with a final static test on April 25 this year.

During the structural tests, engineers used vacuum pumps to simulate the pressure of approximately 140,000 lbs on the structure and subjected it to 120% of the expected flight load.

The team also used photogrammetry tools for the final test, which historically uses strain gauges and extensometers to monitor structural response at distinct points during loading.

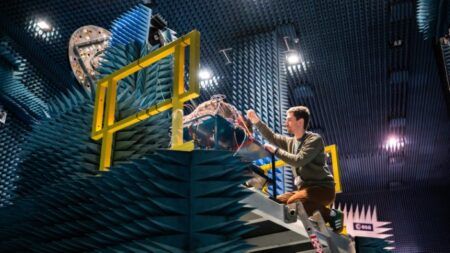

Digital image correlation was used to monitor for full-field strains and displacements over the entire visible area of the heatshield in real-time. To use this technique, a vinyl wrap, similar to a decal, which features dark random speckles over a white background, was applied to the heat shield.

A set of digital cameras was then used to optically monitor any changes in the pattern and generate a three-dimensional map of displacements and surface strains as the applied load increases.

Sotiris Kellas, a NASA Langley aerospace engineer and lead for the technical demonstration said, “While we have used this full-field photogrammetry technique on test articles in the past, this is the first successful implementation on official flight hardware.

“This technology will allow us to safeguard hardware during testing but more importantly provide data for test analysis correlation and improvement of our design and analysis tools.”

The tiles of the Phenolic Impregnated Carbon Ablator (PICA) thermal protection system are currently being applied to the heat shield. Once this is installed and through environmental testing, the full heat shield will be mated to the backshell.

The aeroshell system is the tenth that Lockheed Martin has produced for NASA. Neil Tice, Lockheed Martin’s Mars 2020 Aeroshell program manager said, “Our experience building aeroshells for NASA Mars missions does not mean that it is easy. Tests like this structural one are absolutely essential to ensuring mission success in the long-run.”