The first CST-100 Starliner hull is now one piece after engineers bolted together the upper and lower domes on May 2 as completion of the Structural Test Article approaches. It is the first spacecraft to come together inside Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in the former space shuttle hangar.

Identical to the operational Starliners Boeing plans to build and fly, the Structural Test Article is not meant for spaceflight but rather to prove the manufacturing methods and overall ability of the spacecraft to handle the demands of space journeys carrying astronauts to the International Space Station.

Boeing is one of two contractors chosen by NASA to take astronauts to the International Space Station. Tests with and without crew members will take place before operational missions begin. The end result for NASA will be a larger resident space station crew and a doubling of scientific research time aboard the orbiting laboratory.

The Starliner structural test article will go through final outfitting before it is moved to Huntington Beach, California, where it will be subjected to loads and separation testing. From there the company expects to apply those lessons to the first flight test models of the Starliner, parts of which are already in the manufacturing flow in Florida.

The building techniques used for Starliners are very different from those of past programs and designed to ease manufacturing wherever possible. For instance, rather than build the pressure vessel and then outfit it with electrical and data cables, plumbing and other fittings, those elements are built into the top and bottom halves of the spacecraft. When the domes are joined, the cables, lines and pipes are already in place, saving engineers the time and frustration of having to move everything in through the small hatch and assemble parts inside the closed hull.

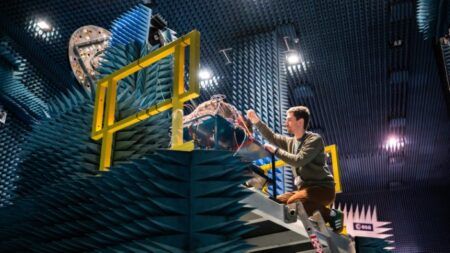

See a video of the assembly of the Starliner here.