Engineers from the US Air Force Research Laboratory and several US universities have found that polyimides, a material used extensively in spacecraft, is severely degraded by the effects of space weather.

The researchers ran tests that determined the previously unknown chemical and physical effects of electron bombardment in Earth’s magnetosphere on these polymers. Electrons trapped in the Earth’s magnetic field are the most damaging components of weather in the geosynchronous Earth orbit.

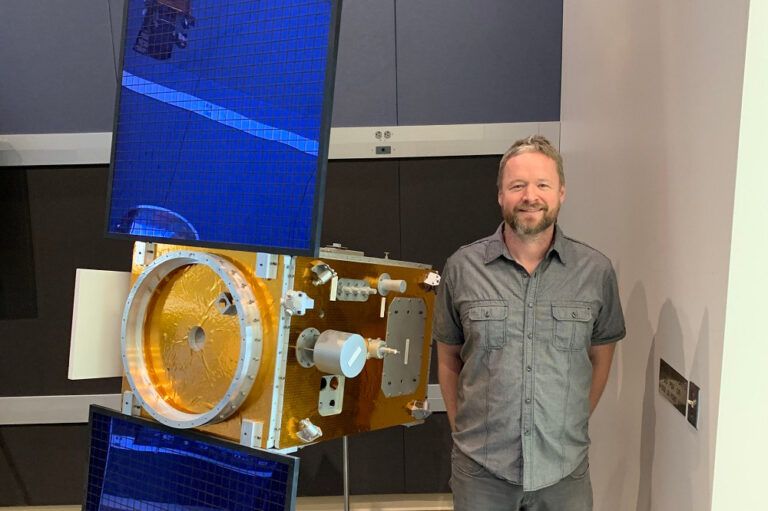

Polyimide films, such as Kapton, are used to construct spacecraft components, including flexible printed circuits, electronics, electronic packaging, wiring and thermal blankets. The material has to endure the extreme and variable radiation conditions present in the operational environment for each spacecraft.

Understanding the processes of radiation damage is a critical part of predicting the long-term behaviors of these products and improving their performance and operational longevity.

Chemical bonds

According to researchers, the stability of the polymer during and after radiation damage is a serious concern. While Kapton is extremely radiation resistant, it suffers serious performance degradation when exposed to the space environment.

While normally flexible within a very broad temperature range from -100˚C to 250˚C when exposed to radiation the material turns brittle and loses its mechanical properties.

The team discovered that when a Kapton sample is irradiated, it changes color from its normal orange-amber to red, indicating chemical changes in the material. However, after several hours of exposure to the atmosphere, the sample turns back to its original color.

It was found that space radiation dose not break every chemical bond in the material and selectively leaves large pieces of the polymer unscathed.

Rexaff modelig

The team captured the effects of radiation damage using a modeling system called Reactive Force Field molecular dynamics known as Reaxff. The modeling system allows them to simulate the process in near real-world conditions. The researchers then correlated these modeling results to experimental characterization, including spectroscopy, thermo-mechanical testing and x-ray diffraction and scattering.

The interpretation of the modeling work combined with the experimental findings led to insights on how to improve the chemical structure of polyimides and create better radiation-hardened materials.

Over the course of the collaboration, the team assembled all of the required modeling and evaluation expertise to move these goals closer to reality.

“The modeling tool could be applied as a predictive tool for other systems that may be used in space or aerospace applications being irradiated by x-rays, gamma rays or electrons,” said Daniel Engelhart of Assurance Technology Corporation. “We are currently working on modeling more complex composite materials under extreme radiation environments.”

“We are also looking at materials which are currently explored as high temperature thermoplastic resins for advanced manufacturing processes,” said Hilmar Koerner, AFRL. “These materials can be processed through an extruder and turned into a part, similar to 3D printing. Such materials have the potential to eventually replace Kapton, but are currently limited due to their high price.”

The research team is now working on improving the consistency and accuracy of the new theoretical models.

The research team from the US Air Force Research Laboratory’s Materials and Manufacturing Directorate and the Space Vehicles Directorate worked with researchers from Johns Hopkins University, Assurance Technology Corporation, Hunter College of the City University of New York and Pennsylvania State University to understand the damage caused by radiation.