Space propulsion developer Benchmark Space Systems is to open a new test and manufacturing facility in the UK.

The facility at Westcott Venture Park, Buckinghamshire will be used to build and test Benchmark’s Starling and Halcyon reusable propulsion systems.

Vermont, USA-headquartered Benchmark and UK-based Space Forge have recently signed a contract to co-develop the reusable propulsion systems.

Space Forge is developing “in-space manufacturing” capabilities to make products that would be impossible to create on Earth onboard its returnable and relaunchable ForgeStar spacecraft.

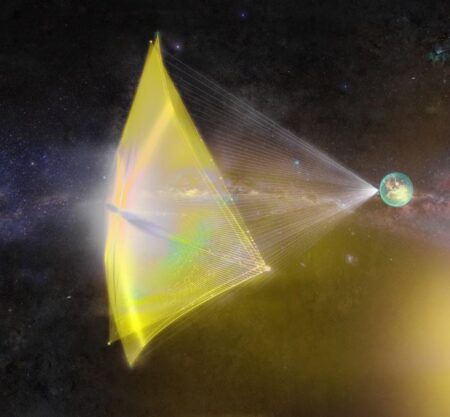

The ForgeStar spacecraft will be deployed from conventional launchers to carry out in-space manufacturing and then return to Earth, propelled by brief and continuous thruster burns, to enable the delivery of products and materials made in space.

Benchmark will provide propulsion for the first SpaceForge in-space manufacturing and return demonstration mission, known as the ForgeStar-1. The mission aims to prove the concept of making products on orbit by leveraging the weightlessness, ultra-high vacuum, and temperature extremes of space.

Benchmark is recruiting extra staff who will be based at its facility, which will be part of the Satellite Applications Catapult facility at Westcott. The company expects to have eight UK-based employees by the end of this year.

The production and shipping of the propulsion systems to Space Forge in Cardiff, Wales and other customers throughout the European region is expected to start later this year.

Mark Arthur, director of European operations for Benchmark said, “Benchmark has kicked off its UK expansion with a landmark contract with Space Forge focused on the development and delivery of reusable propulsion systems to power breakthrough manufacturing capabilities in space.

“We will leverage our team’s expertise abroad and in the USA to enable an exciting mix of missions designed to help our customers and partners around the world solve key challenges, such as in-space production, space debris and collision avoidance.”

Andrew Bacon, Space Forge’s CTO and co-founder said, “Space Forge is transforming the return of satellites and other vehicles from space to enable the production of revolutionary products in key markets that will benefit everyone on Earth, and Benchmark Space System’s proven propulsion systems are a key enabler of our in-space manufacturing mission.”

In the USA, Benchmark has more than 150 propulsion systems ordered and being built during the next 18 months. The company said it is engaged with several space industry companies in the UK and Europe market.

Benchmark’s scalable, propulsion systems are tailored to each customer’s requirements and can support a range of different-sized spacecraft from small CubeSats to 500kg satellites, lunar landers, spent launcher stages, and orbital transfer vehicles (OTVs).