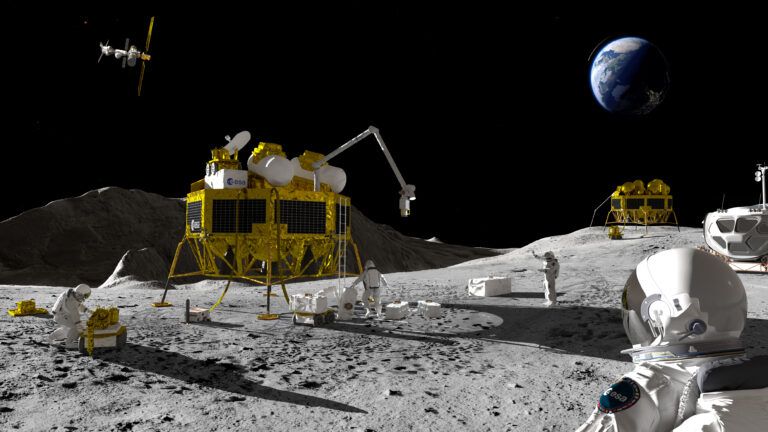

Humankind’s first settlement of the Moon will progress from pressurized landers and rovers to longer-duration bases that look like the International Space Station.

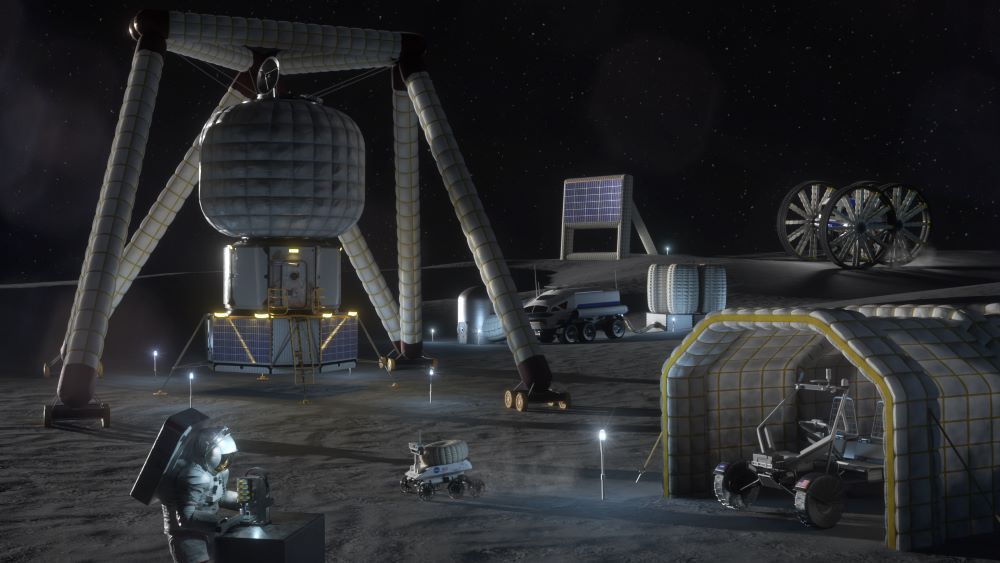

Astronauts will initially live inside the cramped landers and rovers that transport them. But longer-term habitats will feature in situ resource utilization (ISRU) facilities, nuclear fission power plants, and docking for spaceships en route to Mars.

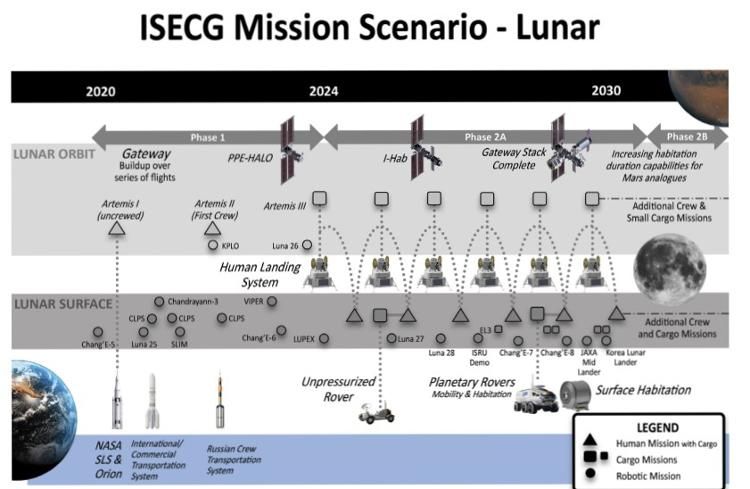

Laid out in the International Space Exploration Coordination Group’s Global Exploration Roadmap, the vision for future moon bases and space stations is the product of people such as the European Space Agency’s (ESA) exploration senior system architect, Markus Landgraf.

“Initial Artemis missions from 2026 will use the lander as a habitat,” said Landgraf. “The first surface habitats will resemble the International Space Station – aluminum cylinders perhaps 10m long and 4m or 5m in diameter.”

The Orion capsule will carry Artemis astronauts into lunar orbit, where it will serve as a platform to assemble the Lunar Gateway space station. NASA has entrusted human landing system development to SpaceX and Blue Origin, founded by billionaires Elon Musk and Jeff Bezos respectively.

Pressurized rovers may use a bipartite architecture: “We put one of those cylinders on a chassis and keep the habitation and mobility modules separate with a clear interface. It is like Orion’s launch architecture, but with wheels and a battery instead of a rocket,” said Landgraf.

Dusty dilemmas

The Italian Space Agency (Agenzia Spaziale Italiana – ASI) expects to provide the first lunar surface habitat for Artemis. Its contractor – Thales Alenia Space (TAS) – is engaged in a study phase.

TAS has developed orbital habitats for 50 years and will also provide elements of the orbital Lunar Gateway. However, surface habitation presents new challenges for engineers.

“We must use an up-down configuration and provide the habitat with mobility,” says Walter Cugno, exploration and science vice president at TAS. “We’re constrained in terms of mass and must deliver the complete element in one launch.”

Moondust, or regolith as it is also known, will attach to external mechanisms and astronauts must decontaminate whenever they traverse the airlock. Regolith is a massive challenge because it cuts seals and textiles, blocks mechanisms and can stick to surfaces with electric potential.

A surface habitat must also function without solar power because lunar nights last fifteen Earth days.

“Power is a major question. Batteries are heavy and occupy space. We can imagine nuclear facilities or solar arrays in space transmitting energy to the surface, but this first element must arrive there completely independent,” Cugno said.

Relying on resources

The International Space Station (ISS) is serving as a testbed for regenerative life-support technologies which recycle carbon dioxide exhaled by astronauts into oxygen, or wastewater into drinking water. Lunar habitats will need these systems to become sustainable.

In situ resource utilization could reduce a habitat’s reliance on deliveries of essentials from Earth, which are mass-constrained and costly.

“The Moon has water, which contains hydrogen and oxygen, and there are rare earth elements to be had, such as thorium and helium-3 for nuclear fuel, as well as abundant aluminum. But for an architecture to work, there must be a business case to support their extraction,” said Landgraf.

Inflatable outposts

However, shipping a nuclear reactor to extract water from regolith and provide drinking water to just four astronauts offers a poor return on investment. The feasibility of a lunar settlement depends on it becoming large enough to produce hundreds of tonnes of water a year, which can be used to make propellant for spaceships, effectively establishing an economy beyond Earth.

Such growth requires a population with diverse skills, which is unlikely to thrive in 10m cylinders. Expanding habitable volume could mean using natural lunar caves or deploying inflatable habitats.

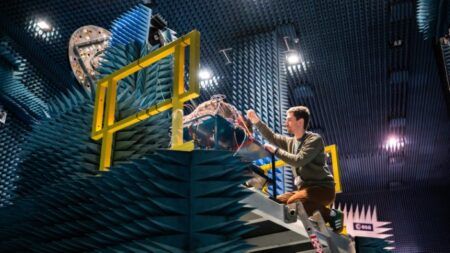

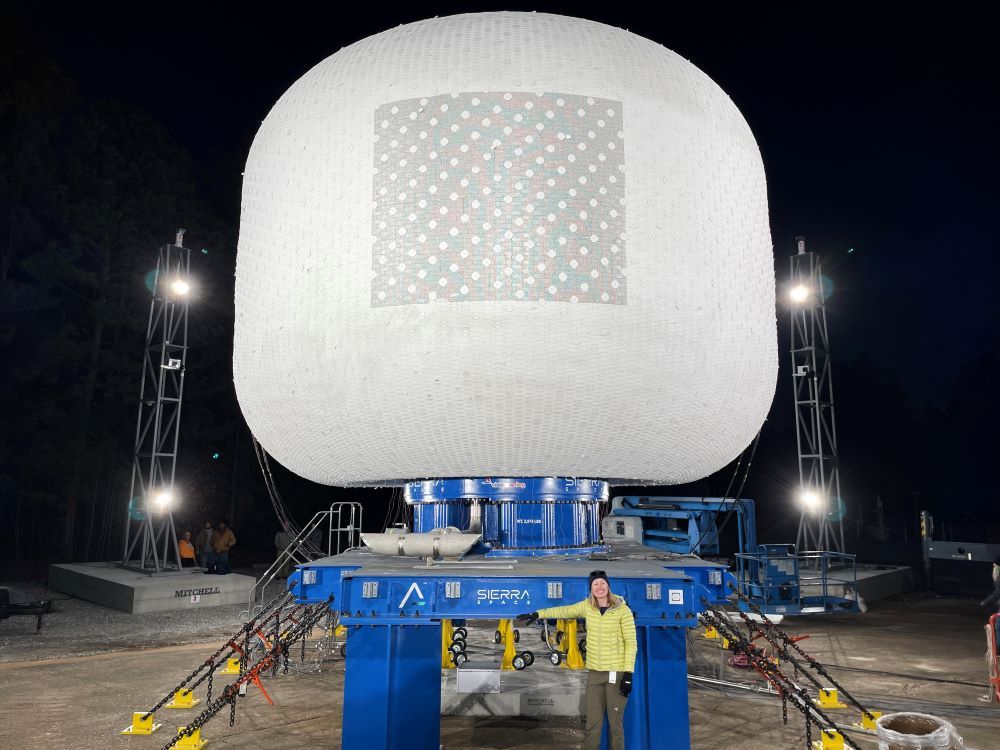

Sierra Space is developing the Large Inflatable Flexible Environment (LIFE). Similar to Bigelow Aerospace technology deployed on ISS, it consists of high-performance fabric layers built around a metal core.

Shawn Buckley, vice president of destinations at Sierra Space said, “Softgoods habitats could provide 100m3 of volume in one launch. We could put that habitat on a lunar terrain vehicle for mobility.

“Inflatables are the wagons and waypoints needed for lunar settlement.”

Spartan Space, a small French startup founded in 2016, is developing the EuroHab inflatable habitat as a temporary shelter or outpost to enable extraterrestrial surface exploration.

“The Moon has safe, flat landing sites, then zones of interest with possible water, or permanent solar illumination. These locations are further apart than the 10km astronauts can safely travel in a rover, so we need secondary habitats between them,” said Peter Weiss, founder and CEO of Spartan Space.

EuroHab would land robotically on rockier terrain and provide a ready-made overnight shelter for astronauts walking to zones of interest. A semi-functional mock up was used to test resupply robots transporting oxygen across a temporary lunar surface created by the ESA in Luxembourg.

“Following another study with the French Space Agency and TAS, we reduced the size and weight of our original 7m diameter structure,” said Weiss. “At an analog site in the Alps, people in astronaut suits ran mission scenarios to test the interior of a second, smaller mockup.”

EuroHab’s airlock will provide dust mitigation, which like a cleanroom may use elevated interior pressure to prevent regolith from entering the habitat. However, during the Alpine tests, insufficient airlock space resulted in regolith contaminating EuroHab’s interior.

Spartan is revising the geometry of its metal core to mitigate the problem. “We must stay within a 1.5-tonne limit. Otherwise, it cannot reach the Moon with a European lander like ESA’s Argonaut,” said Weiss.

Radiation shields

Lunar settlers will also be more directly exposed to solar radiation than ISS astronauts, who remain partially shielded by Earth’s magnetosphere. Artemis missions will therefore be limited to around 30 days and aim to develop effective radiation shielding for use in Moon and Mars missions.

Eventually, burying habitats under regolith may protect inhabitants from radiation, once earth-moving equipment can be flown to the Moon. Landgraf believes 3D printing technology could one day produce spare parts from in situ resources.

But Weiss bridles at some depictions of lunar self-sufficiency: “Artists’ images of greenhouses growing tomatoes on the Moon is science fiction – we haven’t the technology or budget to build it.”

Both Weiss and Landgraf see Europe, once a continent of explorers falling behind in the race to settle the Moon.

“Europe combined cannot even build a human lander,” said Landgraf. ‘If we spent on space what we spend on defense, the UK, France and Germany could each have lunar settlements. It isn’t technology holding us back, but the priority our society puts on exploration.’

‘The Artemis program is funded for six years and by the end NASA must show US taxpayers a sustainable presence on the Moon. Europe could provide that. EuroHab, based on material technology available in Europe today, can be the first house on the Moon,’ said Weiss.