Engineers at NASA’s Armstrong Flight Research Center in California have finished structural tests of the latest wing design for the X-57 electric aircraft.

NASA’s first all-electric X-plane aims to demonstrate the benefits electric propulsion may have for efficiency, noise and emissions. The aircraft is set to arrive at Armstrong this month for verification, taxi tests and then the first experimental flight tests.

Armstrong pilots have already evaluated a standard P2006T Tecnam aircraft in 2015, the first of three configurations for the X-57, for comparison with the electric versions. The aircraft to be delivered this month is X-57’s second configuration, known as Mod II.

Mod II, which is the X-57’s first configuration as an electric aircraft, features electric cruise motors where two combustion motors originally were located. Successful engine tests of Mod were conducted earlier this year at aerospace firm Scaled Composite’s facility in California, USA.

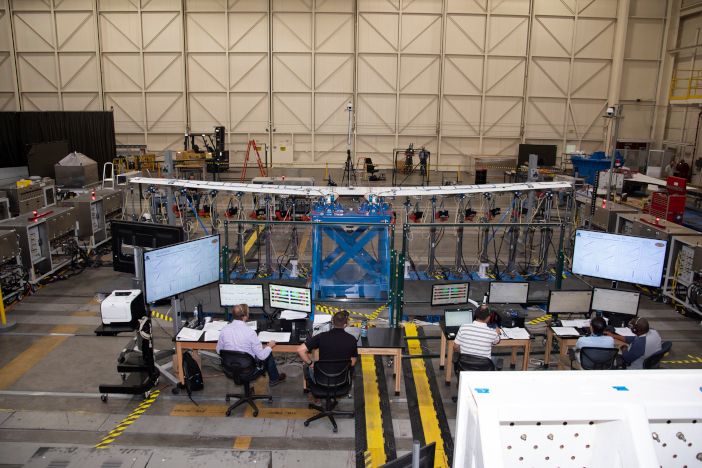

Following the Mod II phase, modification III and IV will feature a high-aspect ratio wing, compared to the wider, standard wing from the Mod II phase. The Mod III/IV wing was tested at Armstrong’s Flight Loads Laboratory to calibrate installed strain gauges for real-time loads monitoring and to verify the wing has met design specifications.

The new wing will permit the repositioning of the electric cruise motors to the wingtips, which engineers believe could significantly boost aircraft efficiency. The Mod IV configuration will include an additional 12 smaller high-lift motors to the two larger cruise motors on each end of the wing to produce distributed electric propulsion.

Built by Xperimental in San Luis Obispo, California, the wing’s major structural load tests involved loading the wing to 120% of the design limit load (DLL) in positive and negative load conditions. Additionally, during 120% DLL testing, the control surfaces were activated through their rotational range to determine if they would bind during the maximum expected flight deflections. Testing revealed that the control surfaces rotated freely through their rotational range.

Image: NASA Photo / Ken Ulbrich

The test fixture designed to secure the wing for testing included 30 hydraulic actuators used to apply load to the wing. In one test that took several hours to prepare, researchers positioned 26 hydraulic actuators – 13 per side – with pads to push up on the wingtip. At the same time, the wingtips were attached to four additional actuators to simulate the inertia and thrust forces caused by the 134 pound cruise motors that will be on the final wing configuration.

Shot bags were used as ballast to create opposing forces to simulate the conditions of about 3.4g inertia that characterize a max design load case. These tests confirmed that the wing structure acts as predicted as it carries the approximately 3,000 lbs aircraft through flight.

Testing on the X-57 wing also marked the first time the lab has used a center-line reaction structure to perform a loads calibration test of an off-aircraft wing, where the entire wing was attached while loading the left and right sides of the wing. The reaction test fixture was conceptualized, designed and fabricated in about a year.

Wing testing also included weight and balance measurements and ground vibration testing. The weight and balance measurements determine the total mass and the center of gravity on the wing, which helped NASA verify that the aircraft will perform as expected during taxi and flight tests.

Ground vibration testing (GVT), considers the engineering challenges of the relatively thin, high aspect-ratio wing, which could be prone to flutter and other vibration conditions in flight. The GVT lets engineers verify whether the structural properties built into the wing matches what is expected for flight.

When the testing concluded, the wing underwent ultrasonic inspection to verify its health before it was shipped back to the project’s prime contractor, Empirical Systems Aerospace (ESAero) from San Luis Obispo, California.

The wing will be integrated into a nearly identical Tecnam P2006T fuselage that came from the same assembly line as the one used in the research, said Trevor Foster, vice president of ESAero. The integration will provide firsthand experience with wiring and flight instrumentation before the integration into the X-plane following the Mod II flights.

“It allows us to practice first and develop a plan,” Foster said. “We can work though many of the difficulties in advance to reduce risk and save time.”

As all of the components are coming together, the question of efficiency and function will soon be answered.