A three-year £15 million (US$21 million) research project to develop a more efficient testing and certification process for aerospace structures.

The Smarter Testing research program is aiming to create a step reduction in development lead-times and costs and brings together the National Physical Laboratory (NPL), Airbus Operations, CFMS Services, GOM UK, Dassault Systemes UK and the University of Liverpool.

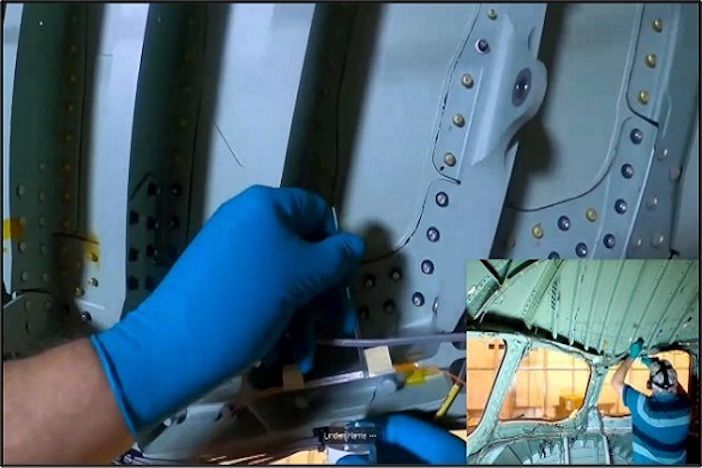

Researchers on the project, which is being funded by the Aerospace Technology Institute will explore how novel inspection techniques can be used to predict product performance and identify failures early by more closely combining virtual and physical testing

Steve Raynes, head of R&T business development at Airbus said, “The opportunity this project presents is huge. It will be a real step change in the way we approach an extremely costly and time-consuming part of a vital aspect of aircraft manufacturing.

“Simply put, we’re going digital across a number of aerospace testing and certification processes. When you consider that to date, a lot of this work has been done on huge physical test rigs which have to be built and maintained, you can easily see how having a digital representation in place of some physical testing can help save time and money.”

Transitioning to an digitalized manufacturing landscape will see an increase in the amount of data used in manufacturing and trust in data will become a critical issue as people and processes become more reliant on it.

The NPL said “it will play a critical role in developing the expertise and standards that enable data to be trusted and used with confidence” by using its test laboratories and applying advanced data science techniques.

Gareth Edwards, strategy lead for industrial digitalisation at NPL said, “The direct benefit of NPL’s work will be the creation and adoption of the technology, skills and understanding needed to innovate and compete within digitalised product development supply chains.

The involvement of the University of Liverpool draws on the H2020 MOTIVATE project which developed technologies that were demonstrated in laboratory conditions and then used in a structural testing of an aircraft subcomponent. It also uses results from the DIMES project which developed an integrated measurement system for online detecting and monitoring damage based on a range of sensor systems.