by Jack Roper

In 1937, the airship’s brief heyday ended abruptly in an airborne inferno. But a new lighter-than-air golden age now trembles at reality’s threshold, thanks to advances in propulsion, flight control, composites, meteorology and computational power. From Google co-founder LTA Research in Akron, Ohio, to Bedfordshire, UK-based Hybrid Air Vehicles (HAV) helium-filled hybrid air vehicle.

HAV’s airship uses electric propulsion and can trace its origin back to the 1990s. “The Airlander 10 uses helium for lift and only expends energy pushing forward, delivering significant fuel-savings over fixed wing,” says HAV’s chief technical officer, Mike Durham. “The downside is speed. We are happiest below 115mph. But that matters less for air freight. We can move goods at 25% of the cost, but it takes us three times longer.”

The Airlander is 100m (330ft) long, 50m (165ft) wide and 28m (90ft) high. Lightly pressurized helium fills the dual ellipses of its ample rump and acts as a lifting gas. Air-filled ballonets maintain internal pressure as the helium expands and contracts. Once aloft, 500hp diesel engines at its four corners propel the ponderous hybrid in forward flight.

“In the airship world, bigger is better,” says Durham. “Doubling our length would create four times the drag, but eight times the gas lift. Starting at a modest size, suited to carrying 100 passengers 186 to 250 miles is

a low risk step. Ultimately, air freight may be our

biggest market.”

Diesel to electric

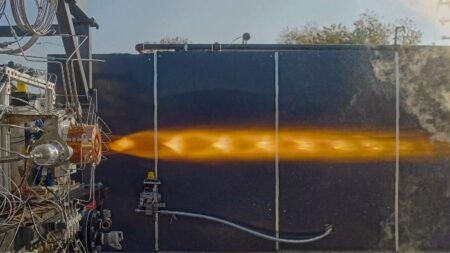

The Airlander is based on the defunded US Army Long Endurance Multi Intelligence Vehicle (LEMV), the first and only hybrid airship ever built. HAV acquired, modified and flew it from Cardington Airfield, UK in 2016 and 2017. Initially diesel-powered, it will transition to electric propulsion. HAV is already developing a 500kW electric motor and controller with Collins Aerospace and Nottingham University.

“In fifteen years, we won’t be discussing CO2, but efficiency in flight,” says Durham. “We will always use about a quarter of the energy and still put less burden on infrastructure than electric aeroplanes.”

A 140m (460ft) Airlander 50 with 50 ton payload capacity is envisioned for air freight. But the Airlander 10 will serve mobility and expeditionary tourism markets. Sailing below 9,850ft (3,000m), passengers will be able to open windows in its non-pressurized cabin, untroubled by vibration or turbulence. More yacht than airplane, the Airlander will gently land on grass or water.

“We want to avoid noisy, congested airports,” Durham says. “Many cities are close to bodies of water. We could land on the Thames Estuary, then a high-speed water-taxi takes you into London.

“We’re keen to make friends with low carbon water people. We fit in with everyone and don’t aim to make airplanes or boats redundant.”

Ordinary airships

French company Flying Whales first conceived the LCA60T (Large-Capacity Airship, 60 Tons) to serve the timber industry. At 200m (650ft), it is twice the Airlander’s length. Helium-filled cells inside its gargantuan hull provide lift, while 32 distributed 4m (13ft) diameter propellers enable horizontal flight.

“We are a conventional airship,” says Flying Whales’ overall airship design leader, Nicolas Weisse. “HAV use both aerostatic and aerodynamic lift and must move forward to fly. But we use only aerostatic lift from the helium.

“We’re always at equilibrium – our aerostatic lift remains equal to our weight. We use propulsion only to manage noise around the equilibrium. Our bones are the airship structure, our skin keeps the environment out while inside, our helium-filled lungs are breathing.”

Though primarily low-flying, the LCA60T can attain 3,000m sailing altitudes in the forest clothed mountains of France. Exclusive reliance on aerostatic lift enables it to hover above wooded locations to exchange loads, though doing so creates some complications.

“As logs are unloaded, the airship becomes lighter and rises,” Weisse says. “We must compensate and maintain equilibrium by taking on 60 tons of water.”

A water truck will pump up to 60m3 of water from the ground into four ballast tanks along the LCA60T’s longitudinal axis. Previous airships carried water to jettison, compensating for lifting gas leaks in an emergency. Ballast system valves and pumps allow the pilot to balance the weight of

the airship, whose massive inertia minimizes risk of sloshing. As logs are loaded the process is reversed.

“We will spray water over a wide area to ensure people below do not receive a swimming pool on their heads,” says Weisse. “It will be like normal rain in the forest.”

The design principles of airships are well understood, so development presents few fundamental engineering challenges. Excepting hull design, which requires some specialized know-how, the Airlander is a largely conventional aircraft. It uses aluminum, carbon fiber and electrical systems standard to the aerospace industry, from which HAV draws most employees.

“Our flight is comparatively benign,” says Durham. “We design at 1.5 g and tend to be stiffness driven.”

“We have submitted our functional hazard analysis and will be certified to the same safety standards that conventional aircraft are,” Durham added. “But the risks are an order of magnitude fewer: a catastrophic tear certainly ruins your day, but still leaves you with a huge parachute with some level of entrained helium in it over your head. We crash slowly.”

Flight testing

HAV and Flying Whales have joined forces to develop EASA SC-GAS regulations issued in January 2022, paving the way for type-certification. Flying Whales has completed its preliminary design review and will start building an airship at its Nouvelle-Aquitaine production factory in 2023. Qualification and certification

flight tests are expected in 2025 and entry-into-service during late 2026.

HAV learned much from flying the LEMV. Designed for prolonged intelligence surveillance and reconnaissance (ISR) at 6,000m (19,685ft), it underwent 500 modifications as a prelude to passenger missions. The US Army intended an essentially unmanned aircraft capable of manned transit through civil airspace, but HAV converted it to a simpler, piloted aircraft.

“Our flight testing sucked knowledge from the first ever full sized hybrid,” says Durham. “We tried to understand aircraft behavior, climb and descent performance, fuel burn at different speeds, how the hull deflects or absorbs energy. We learned to maintain it on the ground. We have used that data in our simulators and to modify our production aircraft.”

But disaster struck one November night in 2017 when the ground crew failed to secure the aircraft. It slipped its moorings and sustained irreparable damage, perhaps in a doomed reprise of its unmanned days. HAV’s principal asset was no more.

HAV introduced automated systems to prevent any future mooring-mast detachments. “We’re a no-blame business,” says Durham. “It was a heavy blow, but proved to be a golden opportunity. Looking after that aircraft consumed virtually all of our energy. We’ve had the luxury, these last three years, to really understand and develop the learnings we extracted from it.”

Recent aerodynamic tests at the Mercedes Grand Prix team’s Silverstone wind tunnel addressed the LEMV’s twitchy pitch-response. HAV tested a new hull shape, modified to improve pitch characteristics. Engineers will use CFD modeling to analyze the full-sized aircraft behavior. HAV is also using subscale

tests to redevelop the LEMV’s landing gear.

“The LEMV was focused on persistent, unmanned, high-altitude missions so the landing gear was just parasitic weight anyway,” says Durham.

“Its rudimentary design was not well damped or stiff enough for a mobility aircraft. We redesigned and repatented it to provide predictable landing capability.”

Flying Whales have developed the LCA60T chiefly through simulation so far. “The size makes prototyping difficult,” Weisse explains. “A scaled LCA60T prototype which lifted 10 tons instead of 60 tons would still be over 100m [330ft] long and require a vast factory to build. We will build the 200m [660ft] aircraft directly and use the first one as a prototype.

“We run tests for behavior we have difficulty simulating, like payload and airship oscillation during load-exchange,” says Weisse. “They excite each other and are affected by inertia and gusts of wind. We will test our damping system to validate simulation of log oscillation. We have a scaled gas cell test ongoing.”

Material matters

The LCA60T’s lungs are fourteen helium cells which expand and contract with altitude and pressure differentials. On the ground, they remain small, but become fully deployed at altitude.

“We made a slice of airship with one third size gas cell inside,” says Weisse. “We will validate installation, fabric tightnesses, deployment inside the structure, helium purification. We have much better materials than a Mickey Mouse balloon, but must still remove some air which gets in.”

The Airlander’s hull is made of Vectran, a woven material developed for yachts competing in the America’s Cup. The hull is impregnated with urethane and carbon black for UV protection, layered with Mylar for gas retention and Tedlar for weather protection.

The hull materials have been subjected to specific tests to ensure a high safety margin. Other material tests are more conventional.

“The hull is welded in segments,” says Durham. “We do hot, wet, long-endurance tests. We put a coupon with a welded joint under flight-load at maximum operating temperature and humidity for ten or twelve days to see if it combs apart.”

The Faraday cage of a metal-fuselaged airliner is difficult to reproduce on a 100m airship. HAV use a fly-by-light flight control system immune to lightning and electromagnetic interference, inherited from the LEMV. The Airlander 10 can fly on autopilot at fixed heading and altitude, but remains a traditionally piloted aircraft with throttle and side-stick controls. The LCA60T has one load exchange station and two pilot stations, but uses control law algorithms to maintain hovering altitude. Pilot-in-the-loop simulation has shaped both systems.

“We analyze pilot difficulty compared to the old aircraft,” says Durham. “We use the Cooper-Harper ease-of-flying score to assess a normal situation versus suddenly failing two engines.”

These fabulous ships of the air may soon float and putter across real-world skies. “Airplanes have not changed much in 70 years, but the airship world offers many architectures,” says Weisse. “Every few years, we predict a comeback. People ask – why now? There is new environmental urgency. Computing, flight-control systems and materials have evolved. And today, we can predict the weather – an airship’s greatest enemy.”

Moving hydrogen for airship fuel

Most analysts agree that green hydrogen offers the best means of transition from fossil fuels, but transporting it to market remains a challenge, according to studies based on doing so in trucks.

Puna island in Hawaii could convert its abundant geothermal energy to green hydrogen – but has no way to then transport it. Rinaldo Brutoco, founder, chairman and CEO of H2 Clipper suggested floating it over the sea in a dirigible, an idea which eventually grew into the company.

“The Clipper is 300m [980ft] long with a hollow exoskeleton,” says Brutoco. “It exploits hydrogen’s buoyancy as a lifting-gas while carrying up to 400,000 lbs [180,000kg] of liquid hydrogen. Its payload capacity depends on speed, distance and altitude. It uses some of the liquid payload in fuel cells to drive the propellers and travels between 150mph and 300mph.”

The H2 Clipper combines gaseous lift and liquid thrust but only liquid hydrogen has the energy density to compete with fossil fuels. Engineers including Matt Moran, who built the world’s largest cryogenic tank at Cape Kennedy, developed proprietary lightweight technology to fly liquid hydrogen at -250°C (-418°F).

The airship’s closely-guarded design is covered by nine patents embodying 205 separate claims, with several more patents anticipated. Its weight-bearing exoskeleton contains space for hydrogen-lifting gas and tanks of liquid hydrogen which are both cargo and fuel. It was designed using Dassault Systèmes’ 3DEXPERIENCE platform.

“We used CFD to design as close as possible to laminar airflow. We bend the exoskeleton at its midpoint in 360° around the airship, so air flows over it.

“We’ve completed our basic R&D phase. We’re working on manufacturing technologies. We need a 24-story factory with doors at both ends. We will build then fly a 400ft prototype under an experimental license while building the full-sized aircraft,” says Brotuco.