Researchers from Oxford University in the UK have developed a sensor made of sapphire fiber able to tolerate extreme temperatures, that could be used in aerospace applications.

The thin and temperature resistant material could be used in sensors to enable high temperature measurements in jet engines, enabling tweaks in performance to reduce emissions and improve performance.

The industrially grown sapphire thread is less than half a millimeter thick and can withstand temperatures of over 2000°C (3,630˚F). When light is injected onto one end of the fiber, some is reflected from a point along the thread that has been modified to be sensitive to temperature, known as a Bragg grating. The wavelength of the reflected light is a measure of the temperature at that point.

Whilst the sapphire fiber is very thin, in comparison to the wavelength of light it is huge. This means that the light can take many different paths along the sapphire fibre, which results in many different wavelengths being reflected at once.

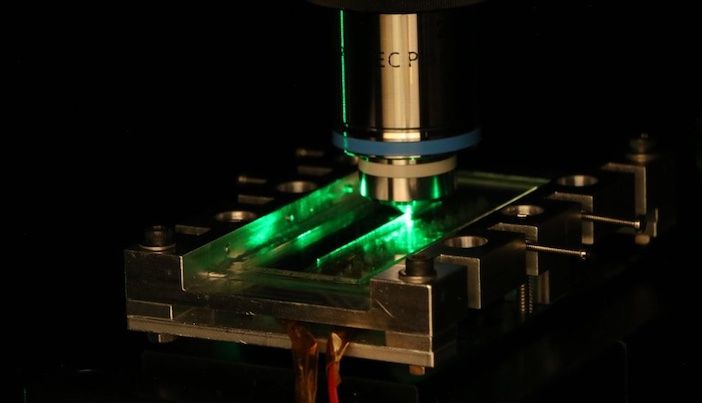

The researchers etched a channel along the length of the thread using femtosecond laser direct writing, so that the light is contained within a tiny cross-section, one-hundredth of a millimeter in diameter. With this approach, they were able to make a sensor reflecting predominantly a single wavelength of light.

Research team member Dr Mohan Wang, from the Department of Engineering Science at the University of Oxford said, “The sensors are fabricated using a high-power laser with extremely short pulses and a significant hurdle was preventing the sapphire from cracking during this process.”

The initial demonstration was on a short length of sapphire fibre 1cm long, but the researchers predict that lengths of up to several meters will be possible, with a number of separate sensors along this length.

Sensors that use the sapphire fiber could produce data that would enable engineers to modify engine conditions in-flight, potentially reducing nitrogen oxide emissions and improving overall efficiency.

The sapphire’s resistance to radiation also gives it possible applications in the space and fusion power industries.

The £1.2 million (US$1.5 million) project was led by Dr Julian Fells at the University of Oxford’s Department of Engineering Science and was carried out in partnership with Rolls-Royce, Cranfield University, Halliburton and MDA Space and Robotics.

Mark Jefferies, chief of university research liaison at Rolls-Royce said, “This fundamental research could in time enable more efficient and accurate multi-point temperature measurement in harsh environments, improving control, efficiency and safety. We look forward to working with the University of Oxford to explore its potential.”

Julian Fells, who is leading the research said, “We are very grateful to the UK Engineering and Physical Sciences Research Council for supporting this work. We are now working with our partners to further develop the technology to the point where it can be integrated into suitable infrastructure.”

The research paper ‘Single-mode sapphire fiber Bragg grating’ was published this month in the journal Optics Express.