Sandia National Laboratories has successfully demonstrated a new, more environmentally friendly method to test a rocket part to ensure its avionics can withstand the shock from stage separation during flight.

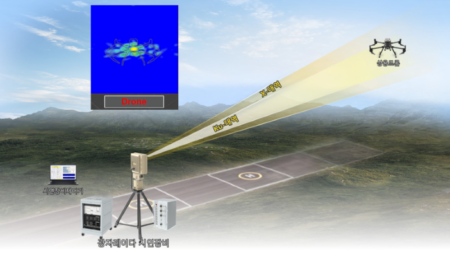

The new method—called the alternative pyroshock test—used a nitrogen-powered gas gun to shoot a 100lb steel projectile into a steel resonant beam, which then transfers energy through a resonant cone attached to the part being tested. The resulting energy transfer mimics the conditions of stage separation in space. The first test of this type using the flight hardware was completed this spring.

Until now, pyroshock tests to ensure aerospace parts were ready for the rigors of flight had used explosives encased in lead to provide the impacts to parts needed for such experiments, said mechanical engineer Mark Pilcher. The lead and explosives were environmental hazards, so cleanup was costly and time-consuming. The Sandia Labs team wanted a better approach.

“We recognized early in the program that we need to seek out alternative test methods in order to reduce our hazardous work exposure, minimize environmental waste and develop a controlled and repeatable test capability,” Pilcher said.

“Investigating a large-scale nonexplosive gas gun test became a reality when we partnered with Sandia’s large-scale mechanical test facilities. The combined team worked hard to get to this test.”

Hopkinson bar technology proved a more controllable alternative to explosives

Asked to research whether an alternative means of testing was possible using a gas gun, Sandia mechanical engineer Bo Song turned to a 1in-diameter Hopkinson bar. The Hopkinson bar was first suggested in 1914 by Bertram Hopkinson, a British patent lawyer and Cambridge University professor of mechanism and applied mechanics, as a way to measure the pressure produced by explosives. It was further modified in 1949 for dynamic stress-strain measurements of materials.

In Sandia’s Experimental Impact Mechanics Laboratory, Song and his team conducted small-scale testing with a metal rod about 20 times smaller than that used in the full-scale test. They discovered the Hopkinson bar technology could provide the frequency levels and the mechanical energy needed in the large-scale test to recreate conditions found during flight.

Song’s team conducted more than 50 tests. They looked at what types of projectiles to use, how fast the gas gun needed to shoot, how to design a Hopkinson bar-type apparatus called a resonant bar at a larger scale, how to design a steel resonant cone to transfer the energy to the object being tested, and how to manipulate the pulse of energy using small copper ‘coins’ called programmers or pulse shapers, which were placed on the surface of the resonant bar.

“The most difficult part was designing the programmers, or pulse shapers, because we had to select the right material, geometry and dimensions,” Song said. “We got a lot of experience through this kind of testing for the future large-scale testing. The same concept can be used for a variety of defense and space applications. This provides a new path for pyroshock testing, but very clean and more controllable, and will save a lot of costs.”

The next phase of the alternative pyroshock test applied the Hopkinson bar technology to a pneumatically driven gas gun.

For this test, the gas gun was not required to reach its maximum capacities. The 60ft-long gas gun used compressed nitrogen gas to shoot metal projectiles into a resonant beam coupled with a resonant cone to expand the final diameter to interface with the rocket part, essentially a hybrid version of a large-scale Hopkinson bar.

September 6, 2017