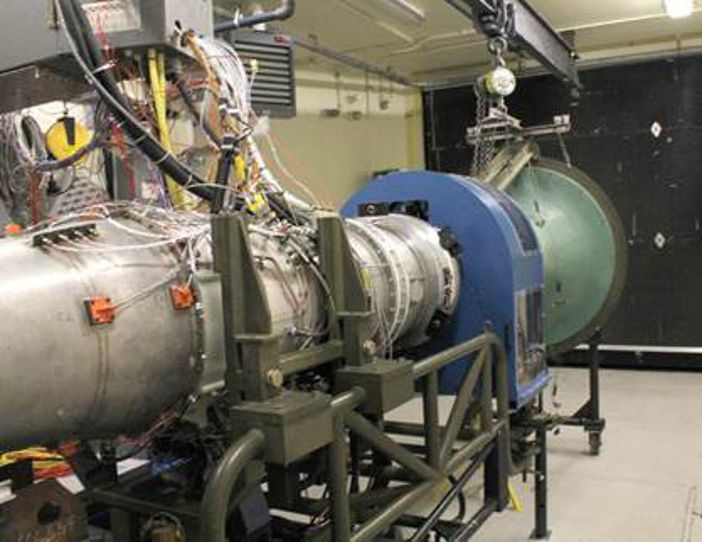

An Arnold Engineering Development Complex (AEDC) test team and members of the US Air Force Academy (USAFA) initiated a project in 2011 at the Academy’s F109 turbofan test facility applying swirl distortion to the determination of engine response in terms of aeromechanics, operability and performance.

In June 2017, the AEDC test team returned to the F109 test facility and conducted a test using a fully functional and automatic swirl generator prototype to determine the response of the F109 engine to swirl with and without pressure distortion.

A set of pre-test predications were also computed that aided in test planning and provided guidance in the test process to determine the best expenditure of test resources.

Dr Milt Davis, technology transition manager with the AEDC test and analysis branch, explained that the Society of Automotive Engineers (SAE) S-16 Committee, also known as the Turbine Engine Inlet Flow Distortion Committee, has been providing for over 30 years methodologies and standards for the aircraft and engine community to use in testing and analyzing inlet distortion effects on gas turbine engines.

“They’ve been largely focusing on the performance and operability aspects of inlet-engine compatibility,” Davis said. “Many gas turbine installations can generate significant flow angularity or swirl as well as total pressure distortion at the Aerodynamic Interface Plane. These issues prompted the SAE S-16 Committee to embark on the development of a methodology for considering swirl as part of the inlet-engine compatibility assurance process.”

AEDC and the Air Force Academy partnered together to test engine response to swirl distortion to better serve the turbine engine community by helping to identify the role that swirl might play not only in stability margin loss but in high-cycle fatigue failures.

“These tests provide the SAE data to help substantiate swirl descriptors proposed for stability margin assessments and provide a data set for validating compression system and engine models under development,” Davis said.

At the inception of the F109 engine test project, the AEDC Technology Program was engaged in the development of a swirl distortion generator for use in direct-connect engine tests. The swirl generator development process culminated in the validation of a fully functional prototype. During validation tests, the prototype demonstrated the ability to rapidly establish pre-determined swirl patterns. The ability to remotely set a large number of swirl patterns enabled the comprehensive 2017 F109 engine test.

“In parallel, AEDC test teams also embarked on the application of a turbine engine numerical simulation capable of predicting the response to inlet distortion, known as the Parallel Compressor Simulation,” Davis added.

The AEDC F109 test team was awarded the General Gossick Team Award in July 2017.

September 6, 2017