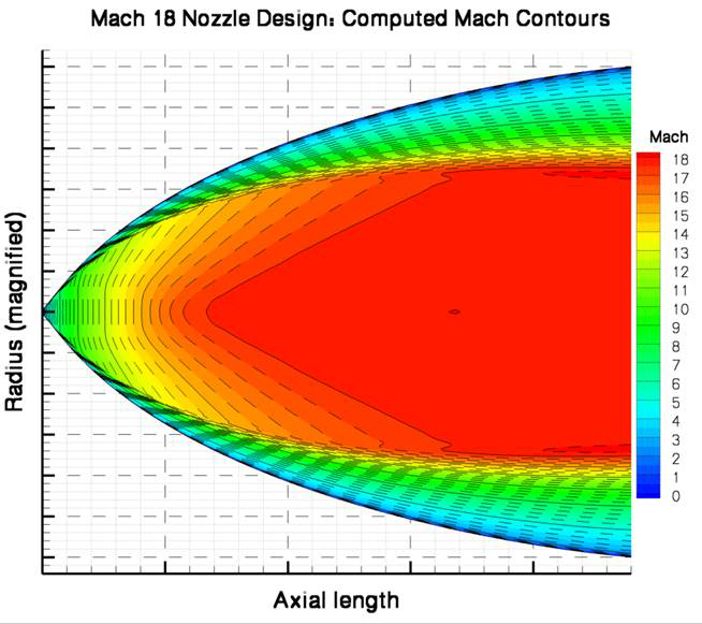

Arnold Engineering Development Complex’s (AEDC) Hypervelocity Wind Tunnel 9 Mach 18 nozzle design has been verified using computational fluid dynamic (CFD) codes. A new nozzle was required to extend the range of desired conditions from the Mach 7, 8, 10 and 14 conditions.

The nozzle was designed analytically to produce the near-uniform conditions in the test section required for the design of advanced future hypersonic weapons. Ken Tatum, AEDC modeling and simulation engineer, said, “Ensuring that these facilities provide high-quality test results at the desired conditions and that the facilities are applicable to understanding extreme flow conditions requires advanced numerical analysis to fill in details that are unavailable from testing.”

The CFD analyses, performed by Tatum and AEDC aerospace engineer Derick Daniel, assessed the physically complex hypersonic flows within the nozzle and showed that a high-quality flow within the test section that is undisturbed by excessive wave reflections is theoretically achievable.

“The thermodynamic chemistry model used in the CFD codes were validated with Coherent Anti-stokes Raman Scattering system test data taken by Andrew Alexander, instrumentation and diagnostics engineer,” Tatum explained.

“Andrew’s measurements verified the existence of non-equilibrium effects at high Mach speeds. We also assessed the effects of pressure waves generated at nozzle joint locations and their effects on the test section for the new nozzle design at equilibrium and non-equilibrium extremes. Accurate modeling of both these effects are critical to building the best nozzle and test capability possible.”

Advanced hypersonic system development will be studied at Tunnel 9. These will include continued advances in the understanding of turbulent boundary layers. High-quality flows will be necessary to provide useful data for such studies. One such diagnostic used to interrogate these boundary layers is particle-image velocimetry (PIV).

November 23, 2017