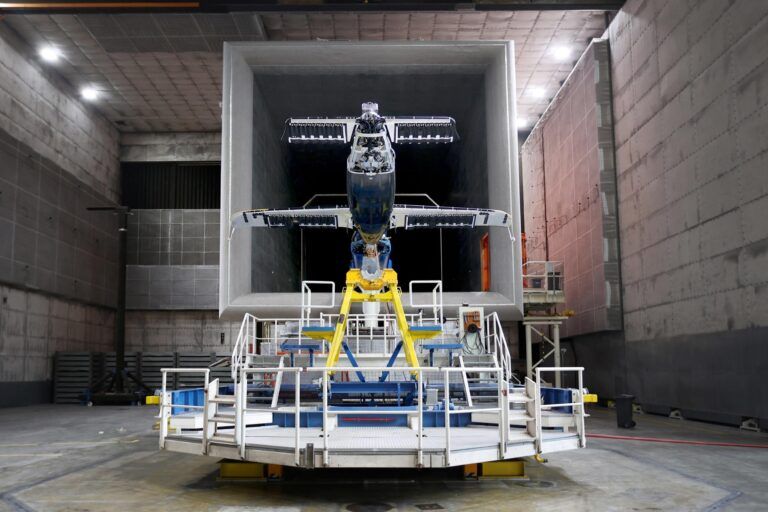

eVTOL developer Lilium has commenced wind tunnel testing of a 1 to 2.5 scale powered model of its Jet aircraft at Europe’s largest wind tunnel in the Netherlands.

The 40% size model includes working engines and flap actuators. Data from the test campaign will cover the complete aircraft flight envelope from hover to cruise and be used to validate flight physics and performance predictions.

The German-Dutch Wind Tunnels (DNW) facility in Marknesse, Netherlands hosts Europe’s largest wind tunnel, which is being used for Lilium’s latest wind tunnel test campaign. The 9.5m-wide (31ft) large low-speed facility (LLF) was built in 1981 and has been used to test all of Airbus’ aircraft and several military jets, including the F-35 STOVL.

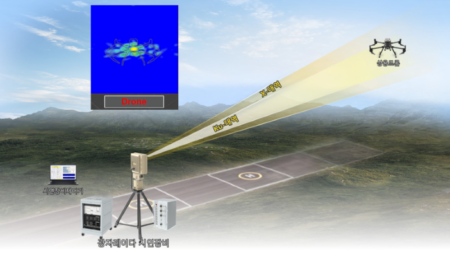

As reported in a recent article with ATI, DNW has recently invested in upgrading its wind tunnels so they can be used to test electric powertrains and eVTOLs.

Lilium has already put aircraft sections through two wind tunnel testing campaigns in 2021 and 2022. According to the company the 40% scale model is one of the most advanced ever to be tested in a wind tunnel. Each flap is remotely actuated and equipped with electric ducted fans built to scale and the model’s large size enables the test data generated to be representative of the full-scale aircraft in all phases of flight.

Lilium plans to start final assembly of a full-scale version of the Jet eVTOL by the end of this year and to begin flight testing during 2024.

Alastair McIntosh, chief technology officer at Lilium said, “This is an important step in our aircraft program and it is very exciting to see this large-scale Lilium Jet model with working engines and wing flaps.

“We’ve been enormously impressed by the cooperation with DNW so far and the support provided by TGR-E and IBK. We look forward to generating vast amounts of aerodynamics data on the aircraft and building further confidence in our design tools, as we prepare for the start of final assembly later this year.”

The model was built by TGR-E (Toyota Gazoo Racing), supported by aerospace design firm IBK-Innovation. The electric ducted fans it uses were supplied by electric propulsion company Schuebeler Technologies