The University of Arizona is to upgrade its hypersonic testing facilities and related aerospace research infrastructure with a US$10 million grant.

The US$10 million in funding is made up of US$3.5 million from the state of Arizona’s investment in the New Economy Initiative and $6.5 million in federal support through the Department of Defense’s (DOD) Test Resource Management Center. The grants will position the university as a leading educational institution in the hypersonics field, said Alex Craig, assistant professor of aerospace and mechanical engineering at the University of Arizona (UArizona).

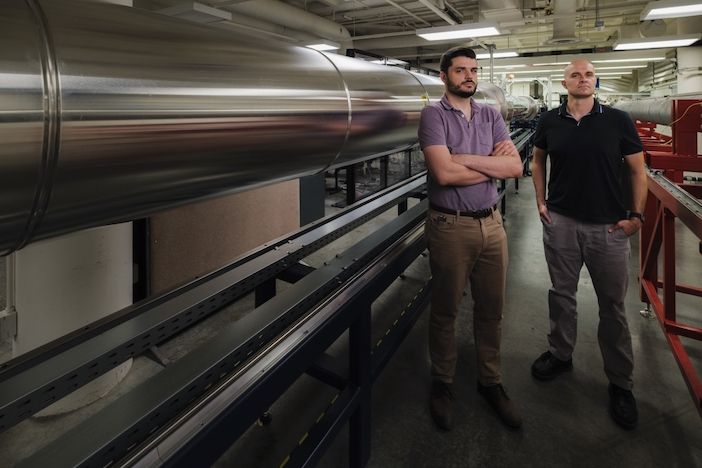

“We’re moving our wind tunnel complex into a more capable realm that you typically don’t see at universities, because it’s usually reserved for government facilities like NASA,” said Craig. “With these upgrades, we’ll be able to provide impactful ground testing services to DOD and its contractors, NASA, and emerging private ventures supporting space and commercial travel, while still fulfilling our educational mission.”

UArizona is home to two hypersonic facilities and additional wind tunnels that permit testing from Mach 0 to Mach 5.

The Boundary-Layer Stability and Transition Laboratory, led by Craig, houses a 15-inch-diameter Mach 5 Ludwieg tube, also known as LT5. The Turbulence and Flow Control Laboratory is led by aerospace and mechanical engineering associate professor Jesse Little. Its most recent addition is the Arizona Supersonic Wind Tunnel, which currently operates at speeds ranging from Mach 1.75 to Mach 4. The Mach number is changed by adding different nozzle blocks – 12 in total – which weigh about 1,800 lbs each.

The funding will support a suite of upgrades for both UArizona hypersonics facilities.

“The University of Arizona is a leader in hypersonics, and this new investment in our unique facilities will allow us to take this exciting research to new level,” said University of Arizona President Robert C. Robbins. “We are grateful for the support of this program from the Arizona Board of Regents, Gov. Doug Ducey and the state legislature, and the funding from the federal government will amplify the impact of Arizona’s investment in this important area of research.”

“As a developer of tactical and strategic missile systems, wind tunnel testing is a core engineering discipline that we employ on nearly every product we design,” said Roy Donelson, executive director and product area director of Strategic Engagement Systems, Strategic Missile Defense for Raytheon Missiles and Defense. “It often becomes a pacing item in our development programs due to a limited number of capable facilities, coupled with high demand across the aerospace industry. These upgrades will enable us to expand our relationship with UArizona to include not only accelerated product development, but also to grow the next generation of aerodynamicists through early, hands-on test experience.”

Mach 5 Nozzle

The university’s Arizona Supersonic Wind Tunnel, or ASWT, has a cross section that measures 15 inches high by 15 inches wide and is the largest of its kind at a U.S. academic institution. Most university wind tunnels of this type are 6 inches by 6 inches or smaller, with only a couple as large as 12 inches by 12 inches. ASWT also can run at six Mach numbers between 1.75 and 4. The new funding will extend its operating range to Mach 5.

In addition, Little recently received funding from the DOD’s Minority-Serving Institution Program to extend the wind tunnel down to subsonic (below Mach 0.8) and transonic (Mach 0.8 to Mach 1.2) conditions. This will enable subsonic, transonic, supersonic and hypersonic testing – transforming the wind tunnel into the Arizona Polysonic Wind Tunnel.

Supersized Air Compression

Moving at thousands of miles per hour, the air rushing through the wind tunnel needs to be compressed and stored in specialized tanks before use. The new funding will allow the university to invest in a system to increase air generation by a factor of 10 and storage capacity by a factor of three. Additionally, the researchers plan to purchase a more sophisticated filtration and drying system, which is especially necessary for operation at Mach 5.

“At present, we can perform one to three 15-second runs per day in ASWT,” Little said. “The new air supply system will increase our capacity to eight to 10 30-second runs per day. This type of throughput is necessary to attract industry, and places us on par with some government facilities.”

Automation to Speed Up Testing

In the LT5 tunnel, which operates at Mach 5, the team can run about five tests a day. Between each test, an operator must reprogram the system to simulate new conditions such as pressure, temperature and model position.

The planned upgrades include a fast-opening valve and automation system that will vastly improve the lab’s efficiency. The system enables an operator to input several pieces of information at once before a series of runs, then have those factors automatically adjusted between runs.

“The automation process is the most exciting part of this, for me,” Craig said. “All of those things are putting us in a realm where LT5 can run 50, 60, 70 times a day with minimal operator input. Similar tunnels at universities can’t get close to that in this type of facility, with the exception of the Air Force Academy.”

Quiet Nozzle to Better Mirror Flight

The funds also will help support the installation of a quiet nozzle for LT5. Currently, the tunnel produces noisy flow, in which the velocity and pressure fluctuations of the air flow are considerably higher than what would be encountered in actual flight. The nozzle, also funded by the DOD’s Minority-Serving Institution Program, will allow the tunnel to create quiet flow, more closely imitating what flight is like in the Earth’s atmosphere.

“The end result is a nationally unique pair of Mach 5 wind tunnels at UArizona offering both quiet and conventional testing at an industry-relevant scale,” Little said.

This article has been edited for style and length from the original by Emily Dieckman, College of Engineering at the University of Arizona, which can be viewed here.