There’s a new space race – albeit much quieter than the one which ran throughout the 1960s. This time it’s not about reaching new frontiers but instead focused on an issue very much of the 21st century: sustainability.

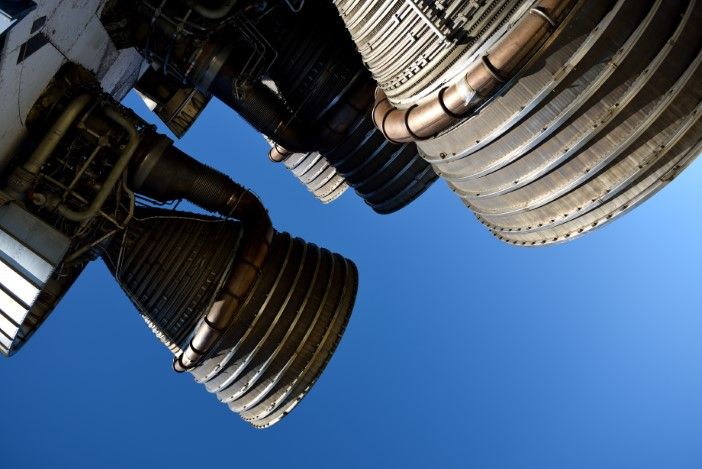

Green thrusters have been a major focus in aerospace since the 1990s, when the potential harms caused by traditional chemical propulsion became clear. Hydrazine, the inorganic compound often used in these systems, is a powerful monopropellant with a high energy density. These qualities have cemented its position as the dominant fuel used in spacecraft over the past 60 years, with many satellite systems still relying on it to this day.

The trouble is hydrazine is dangerous to store, highly toxic and carcinogenic. It presents a major challenge for engineers working on new spacecraft, as well as those responsible for the recovery of crashed legacy assets. The latter might not seem a significant problem until you discover there are roughly 3,000 dead satellites orbiting earth, any one of which could re-enter our atmosphere with little to no warning.

Green thrusters – propulsion systems that avoid the use of compounds like hydrazine – provide a much safer means to power satellites and other spacecraft. And over the past decade, the technology has really started to gather pace, in part due to concurrent breakthroughs seen with precious metal additive manufacturing (AM).

Freedom to create

Traditional subtractive manufacturing is inherently restrictive due to its reliance on machining, casting and welding.

While useful in many cases, these techniques are ill-suited to the development of parts destined for use in the latest propulsion systems. They limit achievable geometries and make it harder to optimise designs – issues that are especially challenging for an industry that’s not only in a constant state of R&D but also in receipt of a significant amount of public money.

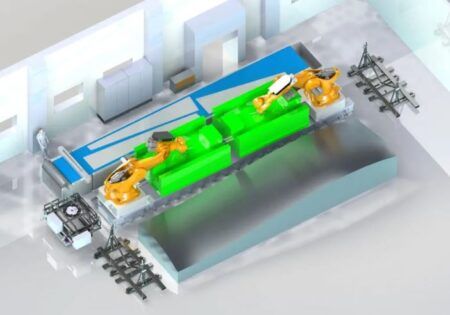

AM easily moves past these barriers, offering a much greater degree of freedom and flexibility in design. This is because the starting material – powdered alloys of precious and non-precious metals – are fundamentally different, only using precise amounts during production, allowing a team to work on prototypes that would otherwise be impossible to achieve.

Platinum, palladium and iridium are all commonly used in thrusters due to their stability, resistance to high-temperature oxidation and excellent catalytic properties. Platinum and iridium are especially valuable because they facilitate the decomposition of green propellants, such as NASA’s AF-M315E and other ionic liquid-based alternatives to conventional fuels. The high catalytic activity of these metals supports a quick, reliable reaction at lower temperatures, which is especially important for fuels like AF-M315E and LMP-103S as they are typically harder to ignite when compared with hydrazine.

Internal lattice structures and microchannel networks are perhaps the best examples of how AM is pushing aerospace development forward. These designs optimise a thruster’s ability to handle heat while also better controlling the flow of propellant gases. Such complex structures are essential for green thrusters, as they improve fuel efficiency and reduce emissions by precisely controlling combustion processes within a satellite.

With subtractive manufacturing, the production of lattices would create high volumes of unused material, not to mention take hours to machine to a satisfactory standard without sacrificing the integrity of a component. Given that the cost of working with precious metals is already high, these traditional techniques are not just impractical but can effectively price-out important parts of the development process. That is, unless engineers engage with experts in this field, like those at Cookson Industrial, who are able to minimise material losses.

Built to last

Precious metal AM is also improving the durability and expected working life of green thrusters. This is another huge advantage for an industry spending vast amounts of time and money on development, not least when some components will only be minor features in a much larger design.

While more environmentally friendly than hydrazine, green propellants still operate at very high temperatures, and some are also highly corrosive. Precious metals, particularly those in the platinum group, exhibit strong corrosion resistance, making them ideal for designs destined to work in harsh environments over long periods. However, to get the most out of these properties, the chosen metals have to be engineered a certain way.

Tighter control of a metal’s microstructure during printing is where AM really comes into its own. Fine tuning a microstructure at a microscopic level – with techniques like laser powder bed fusion – can significantly improve a thruster’s resistance to thermal cycling and fatigue. This durability is particularly relevant for green thrusters that may undergo frequent start-stop operations, such as in satellite attitude control systems or orbital manoeuvring engines.

While not the principal goal for green thrusters, a higher degree of durability is important for lowering the impact of each mission. It leads to longer lifespans and a reduced maintenance programme, as replacement parts are needed much less frequently. Eliminating use of hydrazine is front and centre for this area of research, but added benefits of this kind are still important for the overall sustainability of work in space.

Where worlds collide

AM may be unlocking the full potential of precious metal applications in space but there are several confronting issues for those without the right knowledge or experience.

It will come as no surprise to learn that powdered precious metals are incredibly expensive. Five kilos of platinum – roughly the amount needed to print 6-8g parts – costs around £140,000, though in recent times the price has gone well beyond that due to supply chain pressures. Other potentially useful precious metals, like Rhodium, cost far more simply because they that much rarer.

Good handling practices are therefore critical when working with powdered precious metals. The risk of loss is still high even with good equipment because the amount of material that could send a project’s total cost spiralling is effectively microscopic.

This situation has led to closer collaboration between companies with an established history of working with precious metals and those in aerospace seeking to develop parts quickly and cost-effectively. In Cookson Industrial’s case, the company has been able to print platinum inserts for in-space water thrusters while achieving losses of less than 1%. This is only possible through the use of specially modified machines designed to capture and redirect as much loose material as possible, in addition to strict workflows for personnel that limit contact with all powdered materials.

Green thrusters may still be some way off replacing hydrazine-based designs, though it’s clear this area of research has benefitted significantly with the advent of AM, not least when overseen by those with an expertise in metallurgy.

For more information on precious metal AM, visit: www.cookson-industrial.com