Accelerate your product innovation with HBK – Hottinger Brüel & Kjær - solutions in real-time simulation, physical testing, and predictive insights. From the electrification of mobility to the advancement of smart manufacturing, we support you throughout the entire product life cycle, sharing your mission for a cleaner, healthier, and more productive world. Our journey is continuous, and the ever-growing HBK constellation now includes Dytran sensors for product development testing and embedded monitoring solutions in space and aerospace applications.

Dytran, leading provider of sensors for product development testing and embedded monitoring solutions in space and aerospace applications, is now part of the ever-growing HBK constellation. Accelerate your product innovation with HBK solutions in real-time simulation, physical testing, and predictive insights. From the electrification of mobility to the advancement of smart manufacturing, we support you throughout the entire product life cycle, sharing your mission for a cleaner, healthier, and more productive world.

For more information, please visit www.hbkworld.com

Complete systems from one partner

Complete systems from one partner

Covering the entire measurement chain for comprehensive noise and vibration testing.

- Transducers

- Acquisition hardware

- Vibration shaker systems

- Analysis software

- Final documentation and reporting

Airframes

New materials and designs bring new engineering challenges, making high quality testing assume greater significance – to verify design, troubleshoot problems and approve the product quickly – without compromising safety and comfort.

New materials and designs bring new engineering challenges, making high quality testing assume greater significance – to verify design, troubleshoot problems and approve the product quickly – without compromising safety and comfort.

Exterior noise – Benchmarking, troubleshooting and type approval

- Air vehicle noise certification

- Air vehicle flyover noise measurement

- Exterior noise identification

- Ramp noise

- Wind tunnel testing

Interior noise – Optimising comfort and noise reduction

Interior noise – Optimising comfort and noise reduction

- Occupational health and safety standards testing

- Cabin/cockpit noise assessment

- Human acoustic and vibration monitoring

- Source path contribution analysis

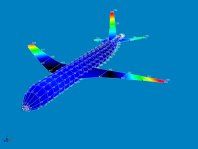

Structural integrity – Linking structural dynamics to Finite Element Analysis

Structural integrity – Linking structural dynamics to Finite Element Analysis

- Ground vibration tests

- Operational testing

- Virtual model validation and updating

- Troubleshooting vibration

Safety and durability – Integrated test solutions

- Acoustic fatigue testing

- Flight testing and monitoring

- Vibration testing for lifetime durability and fatigue limit

- Field data replication, shock and crash testing

- Satellite qualification, shock response testing, modal analysis

Aero engines

Aero engines

As requirements for noise, efficiency, weight and safety are becoming more stringent, remaining within the development budget requires fast and accurate tools that cover the entire design and certification process.

Mechanical health

Mechanical health

- Preventative maintenance and manufacturer-specified checks

- Permanently installed sensors monitor equipment, engine and gearbox conditions

- Balancing, trim balancing, vibration diagnostics

Durability testing of components

Durability testing of components

- Ensuring quality of new material applications with modal testing

- Lifecycle vibration testing of components or whole assemblies

- Fatigue testing for weakness identification