It’s October 2023 and above Montana’s mountainous solitudes, a Boeing 737-10 transects a cold, clear, supersaturated sky. Now, in its wake, comes a second aircraft – NASA’ DC-8 Airborne Laboratory, artfully jockeying to ingest ghostly wisps of contrail. This pursuit across the heavens pertains to contrail formation when 100% sustainable aviation fuel burns in the cleanest lean-burn engines.

“Persistent contrails trap heat in the atmosphere at night and reflect sunlight away by day,” explains Boeing ecoDemonstrator technical lead, Bill Griffin. “But the industry-accepted consensus is that contrails have a global net-warming effect, which could be larger than the effect of CO2 from aviation.”

David Lee is professor of atmospheric science and director of the centre for aviation, transport, and the environment (CATE) at Manchester Metropolitan University in the UK. He and other researchers have estimated the climate impact of contrails within wide uncertainty bands straddling the magnitude of aviation’s CO2 emissions. While burning sustainable aviation fuels (SAFs) made from non-fossil feedstocks emits similar CO2 to kerosene, it purportedly reduces net emissions by up to 80% based on fuel lifecycle analysis.

“SAFs represent our most impactful and least disruptive solution for existing aircraft and infrastructure,” says NASA research scientist, Rich Moore. “Experts speculate that in the near term, SAF may be 100% of the climate solution. Given how slowly the fleet turns over, it may remain a substantial part of the solution even in the 2050s.”

Electrification is unfeasible for long-distance air travel and hydrogen technology is immature and requires changes to engines and infrastructure. SAFs provide a drop-in replacement almost indistinguishable from kerosene. Why, then, would the contrails they produce be any different?

“The answer lies in their chemistry,” Moore explains. “Jet A contains ring-shaped hydrocarbons called aromatics. Impurities in petroleum feedstocks determine its sulfur content, which is variable even within the USA. One theory sees multi-ringed aromatics as a precursor to soot emissions. By virtue of their production mechanism, SAFs typically contain zero sulfur or aromatics.”

Contrail testing

If switching to SAF reduces soot emissions, it should also diminish contrail formation, since soot particles provide the seeds or nuclei upon which supercooled water vapor forms into contrail ice crystals. Boeing, NASA and partners have tested these assumptions in a series of tests over several years.

“We chose a MAX aircraft because the GE Aerospace and Safran CFM Leap-1B engines have the latest generation lean-burn combustors,” says Griffin. “They already reduce particulate emissions versus older combustors. In 2021, we collaborated with NASA to measure emissions on the ground.”

“We drove our mobile laboratory from NASA Langley in Virginia to Boeing Field near Seattle,” Moore recalls. “We parked behind a blast fence while they ran the 737’s engines on 100% SAF. When they transitioned to lean-burn combustion, the soot emissions were hard to discern from background levels. It is an incredibly clean coupling of engines and fuel.”

Now Boeing and NASA looked to test whether ground-observed soot reductions translated to cruise altitudes where contrails form.

This was accomplished in those chilly skies over Montana and Washington State late last year in partnership with the FAA, GE Aerospace, the German Aerospace Center (DLR) and United Airlines. The flight tests took two years to prepare for – not least because aircraft today are only certified to fly with a maximum of 50% SAF to conventional fuel blends.

“Our engineering teams worked to clear the aircraft for 100% SAF operations,” says Griffin. “As an experimental flight with unapproved fuel, it required hazard and mitigation assessments. We configured the aircraft with SAF in the center tank and low-sulfur Jet A in the wing tanks, so we could switch between them.”

SAF produced from waste oils using hydrotreated esters and fatty acids (HEFA) was selected for the campaign. Since this was an airborne chemistry experiment, fuel was handled meticulously to eliminate contamination as a source of variability.

The FAA designated airspace for the experiment over land and the Pacific Ocean. Since contrails only form in regions of cold and supersaturated humidity, flights were planned based on meteorological forecasts received at 4 pm the previous day.

Finally, Griffin and Moore were borne aloft in a campaign remembered with boyish exuberance.

“I was in the rear plane with the experimenters,” says Moore. “We all had headsets and there was a constant interplay.

“The two sets of pilots from two organizational cultures soon found a common communication cadence. We asked the pilots to position us into pinpricks of contrail, indistinguishable in a sea of bright, white cloud.”

Across a total of eleven five to six -hour experimental flights, pilots developed a sixth sense for the ephemeral presence of contrails as their formation flying grew steadily more adept.

“We would meet at a predefined location,” says Griffin. “We often did a loop while the DC-8 caught up. Following an altimeter comparison check, the DC-8 drifted back and followed, sampling our plume. Switching between Jet A and SAF captured back-to-back data under similar atmospheric conditions.”

Aerial instrumentation setup

NASA’s flying laboratory was tooled with a battery of instruments. Laser-based particle counters were important workhorses, but enabling them to detect airborne soot particles 5nm to 20nm in diameter required significant creativity.

“We brought air into the cabin via inlets where instruments were mounted,” Moore explains. “We flowed particles over a hot bath of alcohol which condensed on them, growing them to a size where they scatter laser-light, and we count the blips. Downstream, particles traversed a 350°C (662°F) tube which stripped volatile sulfur and organics from non-volatile black carbon, representing our soot.”

Open-path cloud probes measured contrail ice crystals mounted externally to the aircraft’s belly, passing a laser beam between two arms and detecting scattered light from passing crystals. Spectroscopic laser instruments measured trace gases, while laser hygrometers characterized ambient humidity.

“We concluded testing in November, so that dataset is captured,” says Griffin. “It will tell us what levers we need to pull going forward, then we can craft future test campaigns in areas we would like to understand better.”

Boeing, NASA and partners will spend most of this year analyzing the resulting dataset before making it available publicly. The data could help inform and constrain how climate models simulate aviation and enable weather models to better inform mitigations like rerouting individual flights around contrail-prone skies. Meanwhile, Griffin and Moore’ anecdotal takeaways closely correspond. “We continually measured the background, then entered the lead aircraft’s plume,” says Moore. “Often, no increase in soot particles was discernible over background levels. In real time, the results at cruise altitude bore out our ground-test results.”

Flight100

In November 2023, airline Virgin Atlantic made history with the first ever 100% SAF-powered transatlantic flight of a commercial airliner. The airliner in question was a Boeing 787 and Flight100 was the fruit of a year-long cross-industry project with partners including Boeing and Rolls Royce.

“Flight100 demonstrated the capability of SAF as a safe drop-in replacement for fossil-derived jet fuel,” says Luke Ervine, Virgin Atlantic’s head of sustainability. “We are rightly focused on the levers we have to reduce emissions – and SAF is the only mid-term viable solution for decarbonizing long haul aviation.”

Boeing aims to ensure all its aircraft are 100% compatible with SAF by 2030. For now, commercial aircraft are limited to 50% SAF while potential impacts of higher blends on components designed to work with kerosene are established and mitigated.

“Our fuel quantity indicating systems work off petroleum’s dielectric constant, but paraffinic SAFs can have differing dielectric properties,” says Griffin. “SAFs with lower densities will have implications for aircraft weight and balance. We are also working on long term compatibility of materials.”

Boeing is evaluating all materials that come into contact with SAF to determine if changes are needed. Its fuel systems use nitrile rubber seals which swell through long-term exposure to aromatic compounds in jet fuel. As subsequent contact with aromatic-free SAF may cause them to shrink and possibly leak, the company is developing SAF-tolerant seals. Virgin Atlantic’s Flight100 used a blend of 88% HEFA and 12% synthetic aromatic kerosene (SAK) with high aromatic content.

In 2023, Boeing procured 5.6 million gallons of SAF. The company supports production via initiatives worldwide. For Virgin Atlantic, sourcing enough SAF for just one flight proved challenging and scarcity remains the chief obstacle to wider adoption.

“Flight100 was intended to drive certification for 100% SAF so we can send demand signals to the market,” says Ervine. “It demonstrated that if SAF is made, we can fly it. The biggest hurdle remains lack of production and policy support to attract investment and develop a SAF industry at scale.”

Is SAF a wrong turn for emissions reduction?

Production of SAF undermines global goals of limiting climate warming to 1.5°C, according to a 2023 paper co-authored by Susanne Becken, professor of sustainable tourism at Griffith University, Australia.

Based on an analysis of twelve aviation roadmaps to net zero, the study found producing enough sustainable aviation fuel (SAF) to decarbonize commercial aviation would consume 125 million hectares of farmland and 30% of Earth’s sustainably available biomass.

“Every sector has a roadmap, not just aviation – and there are higher value uses for biomass than burning it in planes,” says Becken. “Since publication, we have seen concern about biofuels as a solution and discussion shift to synthetic fuels.”

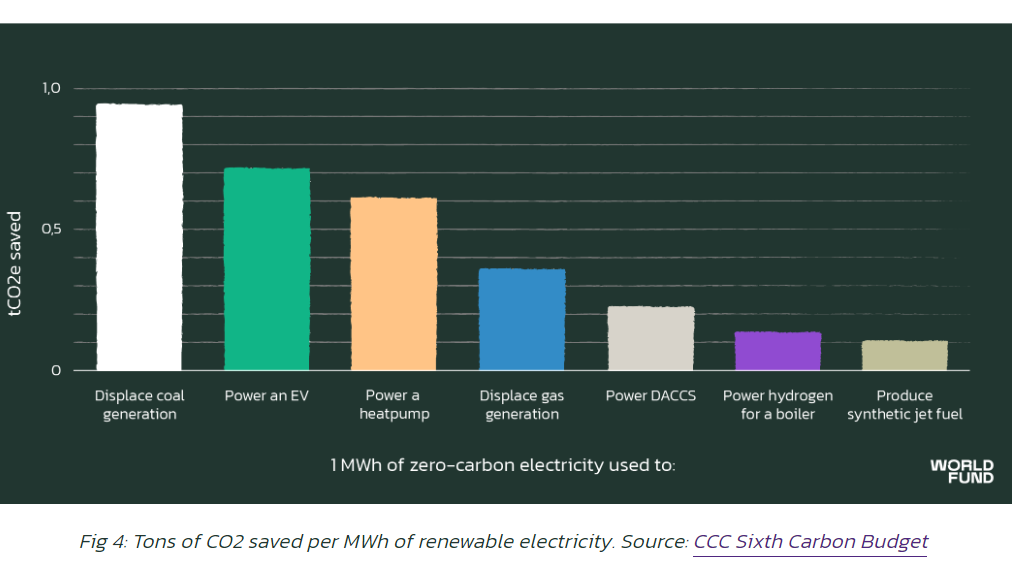

However, energy intensive synthetic fuel production still risks displacing finite renewable energy supplies from more worthwhile applications. The UK’s Sixth Climate Carbon Budget includes a usefully illustrative bar chart.

“It compares CO2 savings achievable by using renewable energy to replace dirty activities. Switching off coal-fired power stations offers the most benefit – ten times greater than producing aviation fuel, which has the absolute lowest benefit. Only 9% of Australia’s electricity is renewable and few countries have a fully renewable supply.

Synthetic fuel production requires a source of CO2, creating another conflict with the need for carbon capture and storage now integral to most models of global climate response.

“Plants in Iceland and Switzerland use air filters to sieve CO2 from the air,” says Becken. “The moment we combine CO2 with water to burn instead of storing it, we are in direct competition with a vital mitigation measure.”

One of Becken’s co-authors, an ecologist, argues that any SAF that releases CO2 at the point of combustion is harmful – even those derived from waste materials such as forestry residues.

“The aviation industry would call wood chip a waste product, and therefore zero carbon,” she says. “But my colleague would disagree because in a natural cycle, wood chip decays and returns carbon to the soil, not into the atmosphere.”

Rather than pursue continued growth predicated on fuels described as sustainable, Becken believes that aviation should contemplate a managed retreat to minimum viable networks based on the realistic allocation of available global resources.

Making jet fuel from sewage

Firefly Green Fuels aims to produce SAF from the inauspicious feedstock of sewage. The UK’s population produces some 8 million tonnes per annum.

“Sewage is usually fermented by anaerobic digestion to produce biogas,” says Firefly’s chief operating officer, Paul Hilditch. “We take the digestate and convert it by hydrothermal liquefaction to a viscous liquid called biocrude. Our upgrading process converts that biocrude to a colorless liquid almost identical to jet fuel.”

UK sewage digestate is spread on fields today, a practice causing run-off into rivers which may soon be phased out. Firefly’s SAF pathway serves a serendipitous coincidence of imperatives, helping decarbonize aviation while relieving utility firms of environmentally problematic waste.

Firefly has attracted investment from low-cost carrier Wizz Air with an off-take contract for future supply and is engaged in ASTM D4054 qualification for new SAF pathways. This involves chemical tests to establish that the fuel qualities such as viscosity, density and flash point are close to those of jet fuel.

“We may proceed all the way to engine and flight testing,” says Hilditch. “It is about demonstrating new routes are safe and consistent – and sewage sludge is pretty consistent the world over, regardless of diet or lifestyle.”

Hilditch stresses the distinction between waste-derived and crop-derived fuels. Whilst farming crops for fuel is increasingly seen as problematic, Firefly’s SAF derives from crops already grown and eaten.

“Plants take carbon from the atmosphere,” he says. “Humans eat plants, or plant-eating animals, then produce sewage sludge. We turn that into fuel, which burns and releases carbon. That happens over a short time and does not increase atmospheric carbon.”

Firefly’s production plants will resemble conventional oil refineries. A UK demonstration plant is planned followed by commercial plants expected to come online by 2030. “We anticipate a UK government mandate that jet fuel must be 10% SAF by 2030,” says Hilditch. “We could probably meet half that mandated demand by converting all the UK’s sewage sludge to SAF. But other waste-derived routes use waste cooking oils, municipal solid waste and industrial waste gases. Between us, we can meet that 10% demand.”

Population density relative to aviation demand fixes the UK’s potential to replace jet fuel at around 5% of total consumption. But Firefly’s modeling suggests it could replace 80% of jet fuel at Mumbai International Airport by capturing sewage from Mumbai’s 25m residents.

“Mumbai does not yet capture all that sewage, but wastewater management will swiftly improve,” says Hilditch. “We want to establish a responsible way for aviation to continue and avoid returning to an era when only the wealthy could afford to fly.”