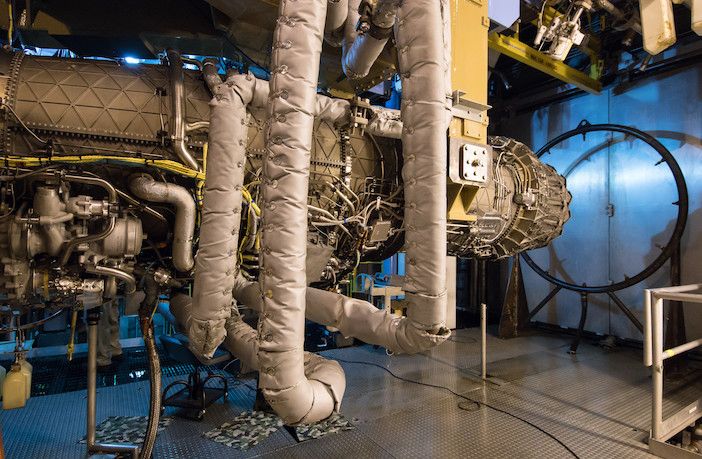

The Pratt & Whitney F135 engine is undergoing another round of testing at the US Air Force’s Arnold Engineering Development Complex in Tennessee.

The F135 powers the F-35 Lightning II aircraft. A new fan rotor added to the engine means it is being put through endurance and accelerated mission testing (AMT) in a sea level test cell at the Arnold Air Force Base.

The test program has been running since last June.

AMT rapidly ages the engine, allowing for the identification and correction of issues before they would occur during normal use. Through AMT, a tested engine accumulates several years of normal life in a short amount of time.

Retired Test Manager Don Corona said, “The whole purpose of an AMT is to put some wear and tear on the engine to simulates what it would have out in the field. But instead of waiting several years to get that, we accomplish that in several months.”

AMT consists of testing at ambient air conditions and under RAM. The term “RAM” refers to the use of test facility compressors to increase the engine inlet pressure and temperature to more closely simulate actual flight conditions.

Corona said RAM simulates high speed travel at a low altitude, allowing engineers to assess how these conditions impact the engine and its components. “RAM conditions ensure that we also have data that is representative of flying at high speed at low altitude conditions, which is actually a harsher environment for the engine,” he said.

The testing has to be completed before the new fan rotor design is installed into the engine of an F-35. “We can’t just take a new design and put it out there on the engines, so this is going to be part of the testing to get it qualified to be put on an engine out in the fleet,” said Corona.

After testing has concluded, the engine will be disassembled and examined.

“When the engine is done testing, they will tear the engine down and they will examine all the components in an analytical condition inspection,” Corona said. “They will look at all the engine components at that time, and they’ll see if the wear on all the engine parts is consistent with what they would expect.”

Testing of the F135, which is sponsored by the F-35 Joint Program Office, is set to continue into 2020. “We are going to be testing it a little bit beyond its normal service life to collect data to support the decision makers with regard to extending the service life of the engine out in the field,” Corona added.

Prior to the testing that began last year, the F135 program had tested well over 5,500 hours in various test cells across AEDC.