French engineers have completed the preliminary design review of the hybrid-electric EcoPulse aircraft, paving the way for the demonstrator’s first test-flight in 2022.

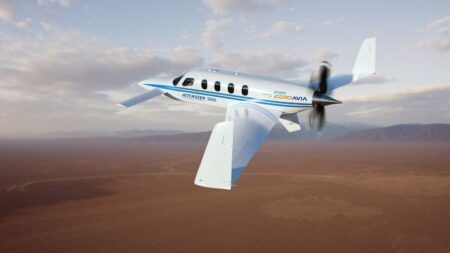

The EcoPulse distributed propulsion hybrid aircraft is being developed by Daher, Safran and Airbus with the backing of the French Government, through the civil aviation research agency CORAC. The demonstrator is based on Daher’s TBM light aircraft.

The completion of the Preliminary Design Review (PDR) is a key first step in the development of EcoPulse, validating the aircraft’s feasibility and firming up the design.

The EcoPulse program was first announced at the 2019 Paris Air Show as part of France’s recovery plan presented last June and is intended, with the aim of “laying the framework for light aircraft by the end of the decade” and :allowing the development of technologies that reduce the environmental footprint of future commercial aircraft”.

Completion of the PDF means aircraft-manufacturer Daher can begin the demonstrator’s assembly late next year at its site in Tarbes, France, with systems supplied by Safran and Airbus. Daher is also handling the EcoPulse’s flight testing.

Meanwhile Airbus,which has been conducting aerodynamic modeling of the EcoPulse, will begin wind tunnel testing of the electric motor, propeller and nacelle before April next year. The electric engine, supplied by Safran, will be tested as well.

The results of these tests will enable the identification of the propeller’s performance characteristics when associated with an electric engine, and validate the engine cooling process.

In addition to the wind tunnel tests, Airbus is planning to simulate the nacelle’s aerodynamic behavior.

Jean-Brice Dumont, executive vice president of engineering at Airbus said, “The EcoPulse demonstrator program, initiated by CORAC with the support of the French DGAC civil aviation agency, is an important step in our ambition to decarbonize the aeronautical industry. It will allow us to study how distributed hybrid propulsion could be integrated into the aircraft of tomorrow and significantly reduce their environmental impact.

Pascal Laguerre, Daher’s chief technology officer said, “With this demonstrator, Daher intends to develop the key architectural principles for future hybrid aircraft. The project reaffirms our commitment, as a general aviation manufacturer with our Kodiak and TBM product lines, to more efficient and eco-responsible aviation.”

Safran is supplying the hybrid-electric propulsion system and has already finalized the configuration of the six electric thrusters to be used. They will be fitted with 50 kW ENGINeUS electric motors with integrated electronics and air cooling, as well as propellers supplied by DUC Hélices. The Safran ENGINeUS motor will be submitted for EASA certification – the same type as granted for a turboshaft engine.

Engineers at Safran will also validate the installation interfaces for the propulsion system’s other components, along with the power management system, the turbogenerator and the high-voltage wiring that will supply electrical power to the thrusters. The turbogenerator, which performed its first test bench runs in 2018, will also undergo additional tests.

“EcoPulse is an ambitious project, and designing hybrid propulsion on this new aircraft architecture is a key skill that Safran is proud to master,” said Stéphane Cueille, senior executive vice president and chief technology officer, research and technology and Innovation at Safran.